-24-

Model G0792 (Mfd. Since 12/15)

Drive Gears

Grease Type ........ T23964 or NLGI#2 Equivalent

Lubrication ................. Every 50 Operating Hours

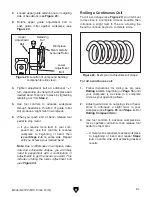

The drive gears, shown in

Figure 29, should

always have a thin coat of heavy grease to mini-

mize corrosion, noise, and wear.

Before lubricating the drive gears, clean them

thoroughly with mineral spirits to remove old

grease. Use a small brush if necessary to clean

between teeth.

Using a clean brush, apply a thin layer of grease

on gears. Make sure to get grease between gear

teeth, but do not fill teeth valleys.

Apply a small dab of grease where gear teeth

mesh together—this grease will be distributed

when gears rotate during machine operation.

Note: If for any reason you need to replace a

gear, clean and lubricate all gears at that time.

Leadscrew

Oil Type .... Grizzly T23962 or ISO 68 Equivalent

Oil Amount ......................................... As Needed

Lubrication Frequency ....................... As Needed

Before lubricating the leadscrew (see

Figure 29),

clean it first with mineral spirits. A stiff brush works

well to help clean out the threads. Make sure to

raise and lower the upper roller, so you can clean

the entire length of the leadscrew.

Figure 29. Leadscrew and drive gears exposed

for cleaning and lubricating.

Leadscrew

Drive Gears

Apply a thin coat of oil along the length of the

leadscrew. Use a stiff brush to apply oil evenly

and down into the threads, then raise and lower

the upper roller to thoroughly disperse the oil.

Note: In some environments, abrasive material

can become caught in the leadscrew lubricant

and drawn into the leadscrew nut. In this case,

lubricate the leadscrew with a quality dry lubricant

such as Grizzly G2545 Silicone Lubricant (see

Accessories on Page 22).

Summary of Contents for G0792

Page 44: ......