-20-

G0803

(Mfd. Since 09/15)

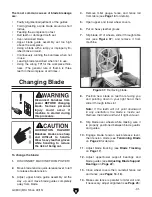

4. Remove switch disabling key, as shown in

Figure 21.

5. Try to start machine with paddle switch. The

machine should not start.

— If the machine does not start, the switch

disabling feature is working as designed.

— If the machine does start, immediately stop

the machine. The switch disabling feature

is not working correctly. This safety feature

must work properly before proceeding with

regular operations. Call Tech Support for

help.

Figure 21. Removing switch key from paddle

switch.

A properly tensioned blade is essential for mak-

ing accurate cuts, maximizing the blade life, and

making other bandsaw adjustments. However, a

properly tensioned blade will not compensate for

cutting problems caused by excessive feed rate,

hardness variations between workpieces, and

improper blade selection.

Optimal cutting results for any type of workpiece

are achieved through a combination of correct

blade selection, proper blade tension, properly

adjusted blade guides and other bandsaw compo-

nents, and using an appropriate feed rate.

Improper blade tension is unsafe, produces inac-

curate and inconsistent results, and introduces

unnecessary wear on bandsaw components.

Over-tensioning the blade increases the chance

of the blade breaking or wheel misalignment.

Under-tensioned blades wander excessively while

cutting and will not track properly during opera-

tion.

The method used to tension the blade is often

a matter of preference. This manual describes

two methods: the flutter method and the deflec-

tion method. Either method will help you properly

tension the blade. Experience and personal pref-

erence will help you decide which method your

prefer.

Tensioning Blade

Note: Tensioning the blade before the Test Run

was an approximate tension. The following proce-

dures fine-tune the blade tension.

Summary of Contents for G0803

Page 56: ...54 G0803 Mfd Since 09 15...

Page 60: ......