-24-

G0803

(Mfd. Since 09/15)

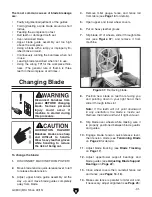

3. Loosen both guide bearing adjustment cap

screws (see

Figure 25), then position guide

bearings so they evenly and lightly touch

sides of blade (see illustration in

Figure 28)

without deflecting it one way or the other.

Note: When the blade guide bearings are

properly adjusted against the blade, they

should lightly rotate as the blade moves.

Figure 28. Blade guide bearings evenly and

lightly touching the sides of the blade.

4. Re-tighten cap screws to secure settings.

Re-check the setting after tightening.

Whenever changing blade or adjusting

blade tension or tracking, the support and

guide bearings must be re-adjusted before

resuming operation to ensure proper blade

support.

Calibrating Miter Slot

with Blade

To ensure cutting accuracy, the table must be

carefully positioned so the miter slot is parallel

with the bandsaw blade.

Before beginning this procedure, make sure

blade is correctly tensioned as described in

the

Tensioning Blade subsection earlier in this

manual.

Tip: This procedure is easier if done with the wid-

est possible blade installed.

Tools Needed

Qty

Straightedge or Carpenter's Square .................. 1

Fine Ruler .......................................................... 1

Hex Wrench 6mm .............................................. 1

To align table miter slot parallel to blade:

1. DISCONNECT MACHINE FROM POWER!

2. Make sure table is perpendicular to side of

blade and is locked in place.

3. Place an accurate straightedge along blade.

The straightedge should lightly touch both

front and back of blade (see

Figure 29).

Note: Make sure straightedge does not go

across a tooth while performing this step.

Figure 29. Placing a straightedge along the

blade and measuring to the miter slot.

Summary of Contents for G0803

Page 56: ...54 G0803 Mfd Since 09 15...

Page 60: ......