-32-

Model G0803Z (Mfd. Since 12/18)

The most common causes of blade breakage

are:

•

Faulty alignment/adjustment of the guides.

•

Forcing/twisting a wide blade around a short

radius.

•

Feeding the workpiece too fast.

•

Dull teeth or damaged tooth set.

•

Over-tensioned blade.

•

Upper blade guide assembly set too high

above the workpiece.

•

Using a blade with a lumpy or improperly fin-

ished braze or weld.

•

Continuously running the bandsaw when not

in use.

•

Leaving blade tensioned when not in use.

•

Using the wrong TPI for the workpiece thick-

ness. (The general rule of thumb is three

teeth in the workpiece at all times.)

To change the blade:

1. DISCONNECT MACHINE FROM POWER!

2. Move blade tension quick-release lever to left

to release blade tension.

3. Adjust upper blade guide assembly all the

way up, and move blade guides completely

away from blade.

Changing Blade

Disconnect bandsaw from

power BEFORE changing

blade. Serious personal

injury could occur if

machine is started during

this procedure.

LACERATION HAZARD!

Bandsaw blades are sharp

and difficult to handle.

Wear heavy leather gloves

while handling to reduce

the risk of being cut.

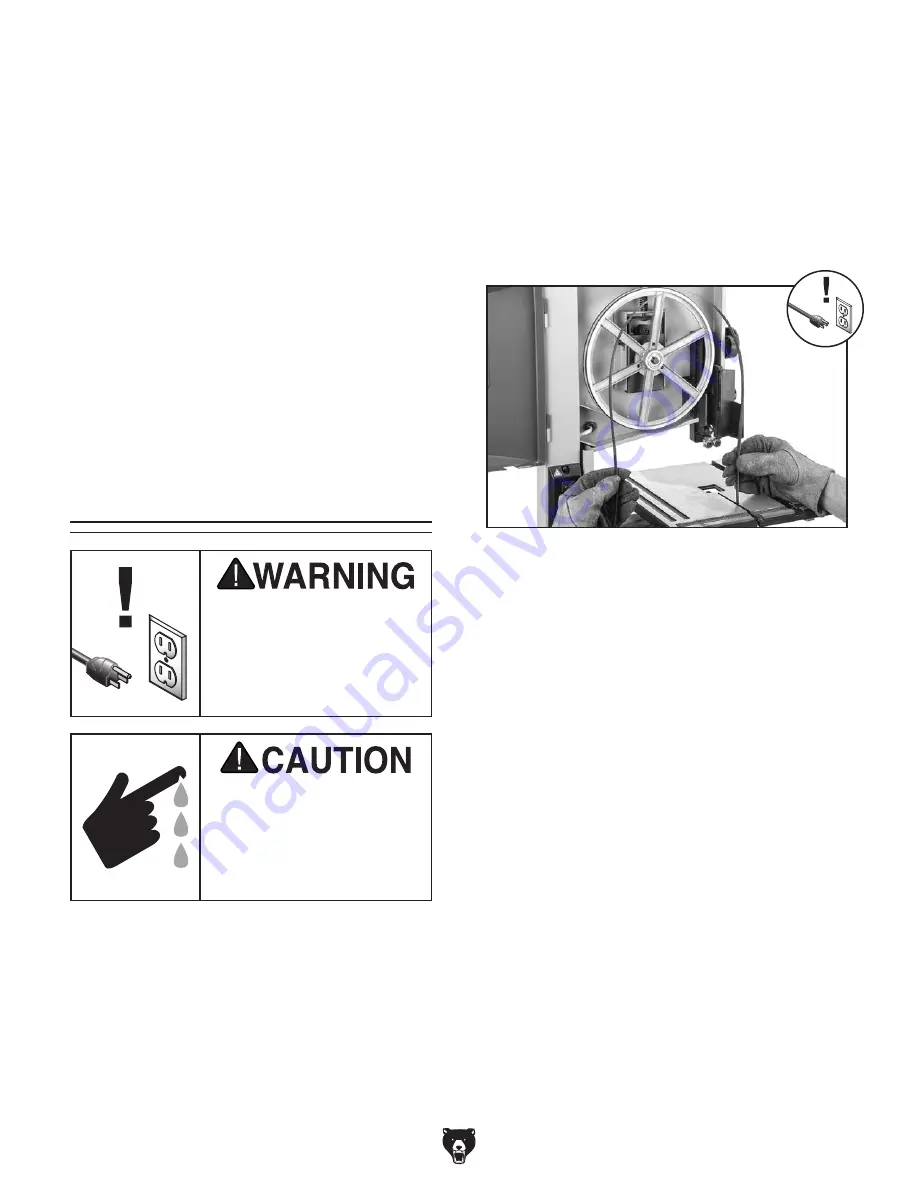

Figure 37. Example of removing blade.

8. Position new blade so teeth are facing you

and pointing down in your right hand, then

slide it through table slot.

Note: If the teeth will not point downward

in any orientation, the blade is inside out.

Remove the blade and twist it right-side out.

9. Slip blade over wheels while making sure it

is properly positioned between blade guards

and guides.

10. Engage blade tension quick-release lever,

then tension blade (see

Tensioning Blade

on

Page 21 for details).

11. Adjust blade tracking (see Blade Tracking

on

Page 17).

12. Adjust upper/lower support bearings and

blade guides (see

Adjusting Blade Support

Bearings on Page 22).

13. Close wheel covers and re-install fence com-

ponents removed in

Step 4.

14. Make sure fence is parallel to miter slot and,

if necessary, adjust alignment (see

Page 26).

4. Remove miter gauge, fence, wing bolt, lock

washer, flat washer, and D-nut from table.

5. Open upper and lower wheel covers.

6. Put on heavy leather gloves.

7. Slip blade off of wheels, slide it through table

slot (see

Figure 37), and remove it from

machine.

Summary of Contents for G0803Z

Page 60: ......