-42-

Model G0803Z (Mfd. Since 12/18)

Symptom

Possible Cause

Possible Solution

Cut is crooked or

blade wanders

(blade lead).

1. Feeding pressure too high or cutting too

fast.

2. Blade tension too loose.

3. Blade dull or damaged.

4. Inadequate blade support.

5. Blade too narrow for cut type.

6. Blade tracking incorrect.

7. Table loose.

8. Fence or miter slot out of alignment with

blade.

9. Blade guides or support bearing incorrectly

adjusted.

10. Tooth set uneven or teeth sharper on one

side than the other.

11. Wrong blade TPI.

12. Blade is following grain of wood.

1. Adjust feed rate and cutting speed as required.

2. Increase blade tension (

Page 21).

3. Replace blade (

Page 32).

4. Adjust upper blade guide as close to workpiece as

possible (

Pages 22–23).

5. Use wider blade.

6. Adjust blade tracking (

Page 17).

7. Tighten table trunnion mounting bolts or tilt lock

lever.

8. Align table and fence with blade (

Pages 25–26).

9. Adjust blade guide bearings and support bearing

for correct blade support (

Pages 22–23).

10. Replace blade (

Page 32).

11. Use a blade with fewer TPI.

12. Increase blade tension (

Page 30).

Blade dulls

prematurely.

1. Wrong blade TPI.

2. Improper feed pressure.

3. Blade is twisted.

4. Blade is slipping on wheel.

5. Guides hitting teeth.

1. Use blade with correct TPI.

2. Use correct feed pressure.

3. Replace blade (

Page 32).

4. Increase blade tension (

Page 30). Clean wheel tire.

5. Adjust blade guide bearings and support bearing

(

Pages 22–23).

Backside of blade

deformation/

cracking.

1. Feed pressure too high.

2. Blade tension too high.

3. Incorrect blade guide alignment.

4. Guides are worn.

5. Blade tracking too far back and hitting lip of

wheels.

1. Reduce feed pressure.

2. Adjust blade tension (

Page 30).

3. Correct blade guide alignment (

Pages 22–23).

4. Replace guides.

5. Adjust tracking (

Page 17).

Sawdust buildup

inside cabinet.

1. Clogged dust port.

1. Clean dust port.

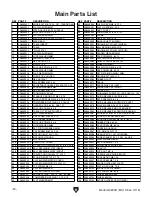

Summary of Contents for G0803Z

Page 60: ......