-52-

Model G0803Z (Mfd. Since 12/18)

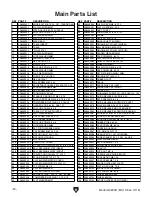

Main Parts List

REF PART #

DESCRIPTION

REF PART #

DESCRIPTION

1

P0803Z001

KNOB BOLT M6-1 X 20, D21, TAPERED KN

50

P0803Z050

PHLP HD SCR M5-.8 X 10

2

P0803Z002

FLAT WASHER 6MM

51

P0803Z051

FLAT HD SCR M3-.5 X 4

3

P0803Z003

MITER GAUGE BODY W/SCALE

52

P0803Z052

DUST PORT 2"

4

P0803Z004

PHLP HD SCR M4-.7 X 6

53

P0803Z053

FOAM GASKET 8 X 5 X 120

5

P0803Z005

FLAT WASHER 4MM

54

P0803Z054

FRAME

6

P0803Z006

MITER GAUGE SCALE POINTER

55

P0803Z055

HEX BOLT M6-1 X 16

7

P0803Z007

MITER BAR

56

P0803Z056

WHEEL SHAFT (LOWER)

8

P0803Z008

TABLE INSERT

57

P0803Z057

TIMING BELT PULLEY (WHEEL)

9

P0803Z009

TABLE

58

P0803Z058

BALL BEARING 6000-2RS

10

P0803Z010

"D" NUT M6-1

59

P0803Z059

TIMING BELT PULLEY (MOTOR)

11

P0803Z011

FLAT WASHER 6MM

60

P0803Z060

FENDER WASHER 5MM

12

P0803Z012

LOCK WASHER 6MM

61

P0803Z061

CAP SCREW M5-.8 X 10

13

P0803Z013

WING BOLT M6-1 X 16

62

P0803Z062

SWITCH MOUNTING PLATE

14

P0803Z014

HEX NUT M10-1.5

63

P0803Z063

GRIZZLY PADDLE SWITCH

15

P0803Z015

PUSH STICK

64

P0803Z064

WHEEL (LOWER)

16

P0803Z016

PHLP HD SCR M5-.8 X 12

65

P0803Z065

PHLP HD SCR M5-.8 X 16

17

P0803Z017

LOCK WASHER 5MM

66

P0803Z066

CAP SCREW M5-.8 X 10

18

P0803Z018

FLAT WASHER 5MM

67

P0803Z067

EXT RETAINING RING 10MM

19

P0803Z019

PUSH STICK HOLDER

68

P0803Z068

TIMING BELT 130XL 10

20

P0803Z020

HEX NUT M6-1

69

P0803Z069

RUBBER FOOT

21

P0803Z021

CAP SCREW M6-1 X 24

70

P0803Z070

SCALE

22

P0803Z022

ADJUSTABLE HANDLE 60L, M8-1.25 X 25

71

P0803Z071

FENCE RAIL CAP (LEFT)

23

P0803Z023

FENDER WASHER 8MM

72

P0803Z072

FENCE RAIL CAP (RIGHT)

24

P0803Z024

CAP SCREW M6-1 X 14

73

P0803Z073

FENCE RAIL

25

P0803Z025

TRUNNION W/SCALE

74

P0803Z074

WORKLAMP W/SWITCH, LED BULB 12V, 1W

26

P0803Z026

STANDOFF-ROUND FF M6-1 X 14

75

P0803Z075

QUICK-RELEASE LEVER 8 X 95

27

P0803Z027

SHOULDER SCREW M5-.8 X 10, 8 X 35

76

P0803Z076

SET SCREW M5-.8 X 6

28

P0803Z028

COMPRESSION SPRING 0.8 X 10 X 25

77

P0803Z077

QUICK-RELEASE ECCENTRIC SHAFT

29

P0803Z029

GEARED KNOB 8 X 39, D46, 12T

78

P0803Z078

WAVY WASHER 16 X 21 X 0.3MM

30

P0803Z030

PHLP HD SCR M5-.8 X 8

79

P0803Z079

QUICK-RELEASE MOUNT BRACKET

31

P0803Z031

TABLE TILT SCALE POINTER

80

P0803Z080

QUICK-RELEASE ECCENTRIC BUSHING

32

P0803Z032

FLAT WASHER 8MM

81

P0803Z081

KNOB BOLT M8-1.25 X 35, D32, 6-LOBE

33

P0803Z033

CAP SCREW M8-1.25 X 14

82

P0803Z082

DOOR LOCK CAM KNOB 40D

34

P0803Z034

LED TRANSFORMER

83

P0803Z083

SHOULDER SCREW M5-.8 X 6, 8 X 12

35

P0803Z035

PHLP HD SCR M5-.8 X 8

84

P0803Z084

RUBBER TUBE 8 X 40

36

P0803Z036

LOCK WASHER 5MM

85

P0803Z085

CAP SCREW M5-.8 X 16

37

P0803Z037

EXT TOOTH WASHER 5MM

86

P0803Z086

CARRYING HANDLE

38

P0803Z038

CAP SCREW M8-1.25 X 20

87

P0803Z087

LOC-LINE 1/2 NPT, 15"

39

P0803Z039

MOTOR 1/3HP 120V 1-PH

88

P0803Z088

HEX NUT M12-1.25 THIN BRASS

39-1 P0803Z039-1

MOTOR FAN COVER

89

P0803Z089

KNOB W/SHAFT 6 X 22, D32, 6-LOBE

39-2 P0803Z039-2

MOTOR FAN

90

P0803Z090

WAVY WASHER 6MM

39-3 P0803Z039-3

CAPACITOR COVER

91

P0803Z091

SET SCREW M4-.7 X 4

39-4 P0803Z039-4

R CAPACITOR 20M 250-350V 1-3/8 X 2-3/8

92

P0803Z092

ADJUSTMENT KNOB SEAT

39-5 P0803Z039-5

BALL BEARING 6201ZZ (REAR)

93

P0803Z093

GEAR 10T

39-6 P0803Z039-6

BALL BEARING 6202ZZ (FRONT)

94

P0803Z094

LOCK NUT M5-.8

40

P0803Z040

POWER CORD 18G 3W 72" 5-15P

95

P0803Z095

UPPER BLADE GUIDE BLOCK

41

P0803Z041

STRAIN RELIEF TYPE-1 1/2

96

P0803Z096

SQUARE NUT M8-1.25

42

P0803Z042

CHIP BLOWER MOTOR COVER

97

P0803Z097

CAP SCREW M6-1 X 8

43

P0803Z043

CHIP BLOWER MOTOR 3.5W 12V

98

P0803Z098

BLADE GUIDE LIMIT PLATE

44

P0803Z044

TAP SCREW M3 X 6

99

P0803Z099

FLAT HD SCR M4-.7 X 8

45

P0803Z045

CHIP BLOWER FAN

100

P0803Z100

BLADE COVER (LOWER)

46

P0803Z046

CHIP BLOWER FAN COVER

101

P0803Z101

CAP SCREW M5-.8 X 6

47

P0803Z047

KNOB BOLT M8-1.25 X 14, D32, 6-LOBE

102

P0803Z102

WHEEL BRUSH SEAT

48

P0803Z048

COMPRESSION SPRING 1 X 13 X 18

103

P0803Z103

WHEEL BRUSH

49

P0803Z049

FLAT WASHER 8MM

104

P0803Z104

BLADE GUIDE BLOCK (LOWER)

Summary of Contents for G0803Z

Page 60: ......