-20-

Model G0812 (Mfd. Since 2/16)

Test Run

Once assembly is complete, test run the machine

to ensure it is properly connected to power and

safety components are functioning correctly.

If you find an unusual problem during the test run,

immediately stop the machine, disconnect it from

power, and fix the problem BEFORE operating the

machine again. The

Troubleshooting table in the

SERVICE section of this manual can help.

To test run machine:

1. Clear all setup tools away from machine.

2. Verify cutting fluid switch (

STAND BY

START

<< I

OFF

1

2

3

4

5

6

7

8

9

0

HIGH

LOW

A

E

M

H

B

C

F

I

J

K

L

G

D

STOP

, D) is OFF.

3. Fill coolant reservoir with coolant (refer to

Page 48), if you have not already done so.

DO NOT run pump without coolant or you will

damage it.

4. Connect machine to power source. Power

lamp (

B

A

C

D

E

F

G

H

I

J

K

L

, A) will illuminate.

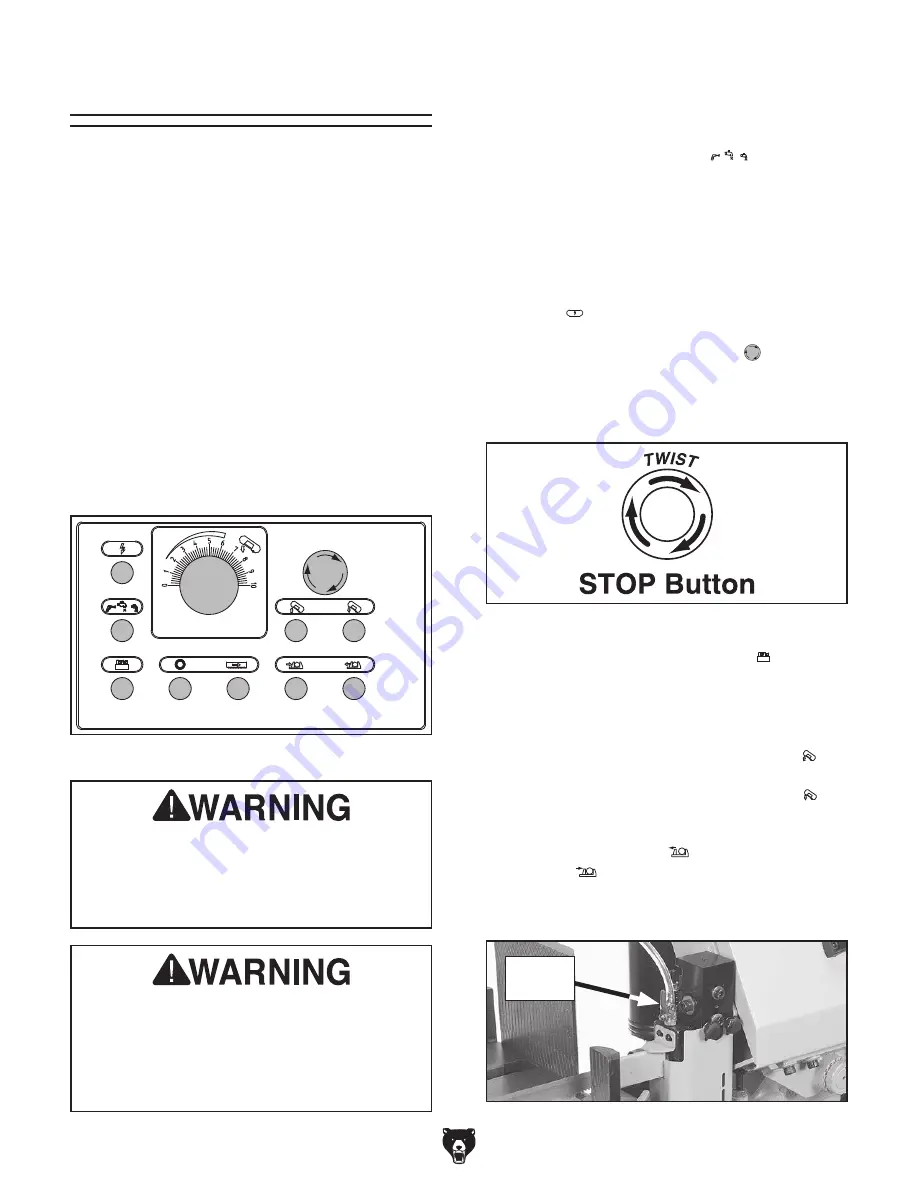

5. Push Emergency Stop button (

B

A

C

D

E

F

G

H

I

J

K

L

, C) in, then

twist it clockwise so it pops out. When STOP

button pops out, switch is reset, and machine

is ready for operation (see

Figure 19).

The test run consists of verifying the following:

1) The hydraulic controls work correctly, 2) the

motor powers up and runs correctly, and 3) the

Emergency Stop button and lower limit switch

work correctly.

Refer to

Figure 18 during test run. Each control

has an alphabetical callout for identification.

DO NOT start machine until all preceding

setup instructions have been performed.

Operating an improperly set up machine

may result in malfunction or unexpect-

ed results that can lead to serious injury,

death, or machine/property damage.

Serious injury or death can result from

using this machine BEFORE understanding

its controls and related safety information.

DO NOT operate, or allow others to operate,

machine until the information is understood.

A

D

G

H

I

J

K

E

F

C

B

Figure 18. G0812 Control panel.

Figure 19. Resetting the switch.

6. Press hydraulic motor button (

B

A

C

D

E

F

G

H

I

J

K

L

, G). You

should hear hydraulic motor (located in

machine base) turn

ON.

7. Check function of saw headstock hydraulics

by pressing raise headstock button (

B

A

C

D

E

F

G

H

I

J

K

L

, E)

setting feed dial (B) at a number over "0",

then pressing lower headstock button (

B

A

C

D

E

F

G

H

I

J

K

L

, F).

8. Check function of vise hydraulics by pressing

vise open button (

STAND BY

START

<< I

OFF

1

2

3

4

5

6

7

8

9

0

HIGH

LOW

A

E

M

H

B

C

F

I

J

K

L

G

D

STOP

, K) and vise close

button (

STAND BY

START

<< I

OFF

1

2

3

4

5

6

7

8

9

0

HIGH

LOW

A

E

M

H

B

C

F

I

J

K

L

G

D

STOP

, J).

9. Open coolant valves (see Figure 20).

Figure 20. Coolant valve (1 of 2) opened.

Coolant

Valve

Summary of Contents for G0812

Page 84: ......