-42-

Model G0812 (Mfd. Since 2/16)

SECTION 6: MAINTENANCE

For optimum performance from your machine,

follow this maintenance schedule and refer to any

specific instructions given in this section.

Daily:

•

Check/correct loose mounting bolts.

•

Check/correct damaged or dull saw blade.

•

Check/correct worn or damaged wires.

•

Clean/protect table.

•

Clean metal chips from upper and lower

wheel areas.

•

Correct any other unsafe condition.

Monthly:

•

Lubricate vise leadscrew (

Page 43).

•

Remove the blade and clean the wheels.

•

Monitor gearbox oil level (

Page 44); check

that oil level is even with halfway mark on

sight glass with headstock in down position.

Yearly:

•

Change gearbox oil (

Page 44).

Schedule

To reduce risk of shock or

accidental startup, always

disconnect machine from

power before adjustments,

maintenance, or service.

Cleaning &

Protecting

Lubrication

The bearings on your bandsaw are factory lubri-

cated and sealed. Leave them alone unless they

need to be replaced.

Always disconnect

bandsaw from power

before beginning any lubri-

cation task.

Use the schedule below and the following instruc-

tions to properly lubricate the other components

that require lubrication.

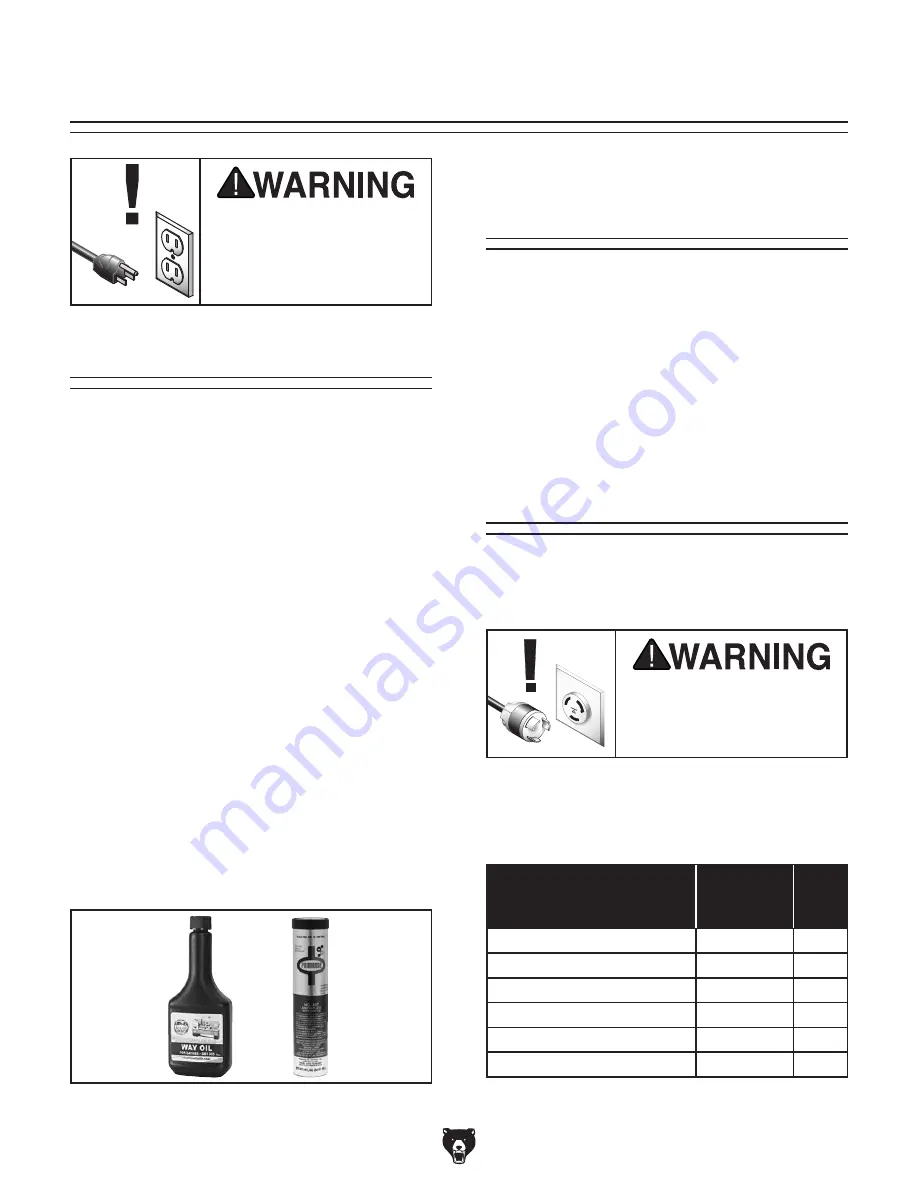

Lubrication Task

Frequency

(Hours of

Operation)

Page

Ref.

Blade Tension Leadscrew

8 Hrs.

43

Blade & Guides

8 Hrs.

43

Table & Vise

8 Hrs.

43

Vise Leadscrew

40 Hrs.

43

Gearbox

50 Hrs.

44

Headstock Pivot Point

8 Hrs.

44

Figure 62. Recommended lubrication tasks.

Use a brush and shop vacuum to remove chips

and other debris from the working surfaces.

Remove any rust build-up from unpainted cast

iron surfaces of your machine and treat with a

non-staining lubricant after cleaning.

Keep unpainted cast iron surfaces rust-free with

regular applications of ISO 68 way oil.

Figure 61. Recommended products for machine

lubrication.

SB1365—South Bend Way Oil-ISO 68

T26419—Syn–O–Gen Synthetic Grease

Summary of Contents for G0812

Page 84: ......