Model G0812 (Mfd. Since 2/16)

-45-

Hydraulic System

The hydraulic system must be maintained on a

regular basis and kept in good operating condition

to avoid premature wear of moving parts, hoses,

and valves.

If you have never maintained a hydraulic system

before, WE STRONGLY RECOMMEND that you

read books, get formal training, or seek the help

of a qualified hydraulic service technician.

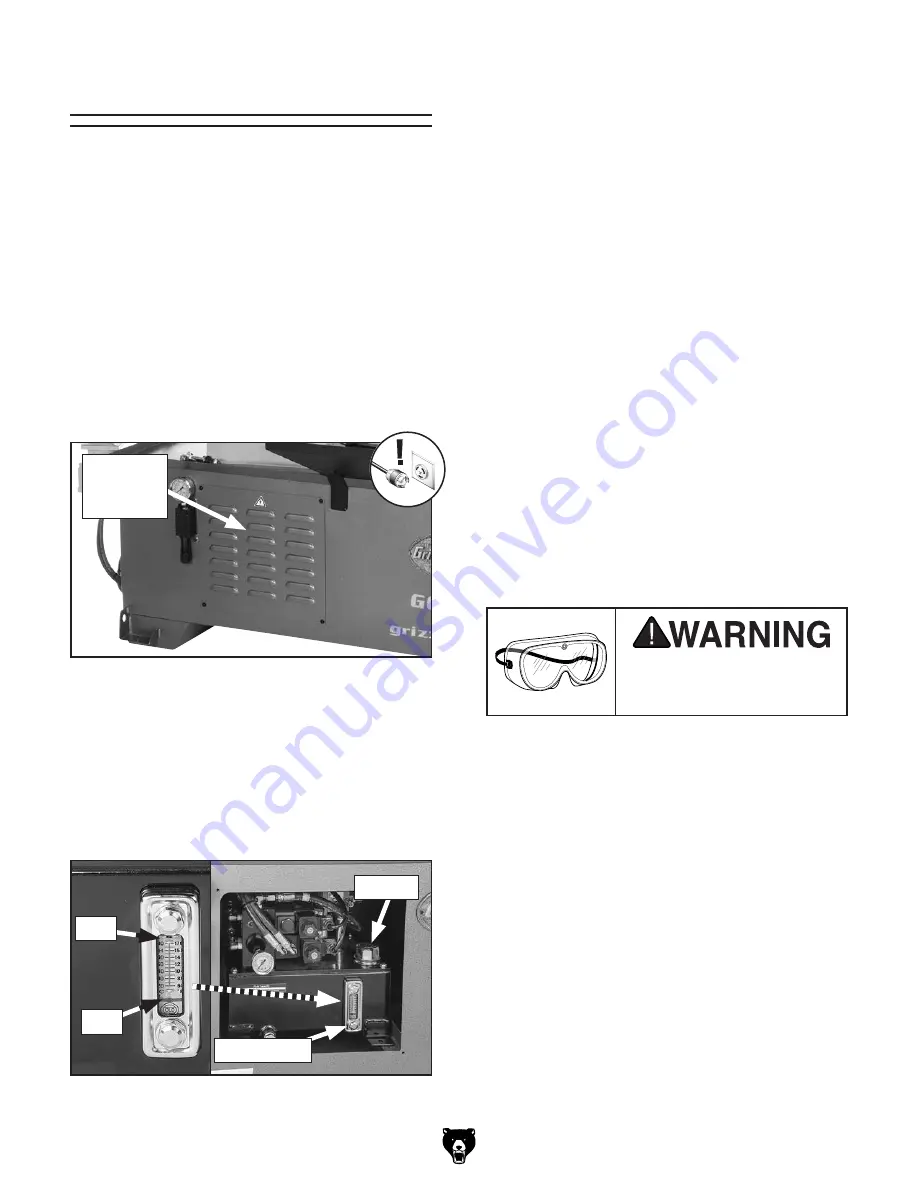

Checking Hydraulic Fluid

1. DISCONNECT MACHINE FROM POWER!

2. Remove front access panel (see Figure 70).

4. Remove tank fill cap and inspect for burnt-

smelling or tan-colored, water-contaminated

hydraulic fluid.

— If fluid is contaminated,

proceed to

Changing Hydraulic Fluid.

5. Re-install tank cap and front access panel.

If this condition continues during operation, stop

using the machine immediately, then review

Troubleshooting on Page 51. If you still cannot

remedy the problem, contact a qualified hydraulic

service technician or our Tech Support.

IMPORTANT: The operating temperature of the

hydraulic fluid should not exceed 140°F (60°C)

with an optimum operating temperature window of

50–95°F (10–35°C). If the fluid temperature rises

above 140°F, stop the machine immediately and

allow the fluid to cool down.

Figure 70. Front access panel location.

Front

Access

Panel

Figure 71. Hydraulic tank fluid gauge and fill cap

location.

High

Low

Fill Cap

Fluid Gauge

3. Check fluid level and temperature on fluid

gauge mounted on front of hydraulic tank

(see

Figure 71). Fluid level indicator should

be halfway between "L" (low) and "H" (high).

— If fluid level is low, proceed to

Changing

Hydraulic Fluid.

Changing Hydraulic Fluid

The hydraulic fluid should be changed after the

first 50 hours of use, then every 5,000 hours of

use after the initial changing.

Items Needed

Qty

3.17 Quarts (3 Liters) ISO 32 or Equivalent ....... 1

1-Gallon Drain Pan ............................................ 1

Open-End Wrench 13mm .................................. 1

Mineral Spirits .................................... As Needed

Air Compressor ................................................. 1

Safety Goggles .................................................. 1

To change hydraulic fluid:

1. Run machine for 10 minutes to warm up

hydraulic oil in tank.

2. DISCONNECT MACHINE FROM POWER!

3. Remove front access panel (see Figure 70).

4. Slide tank out, then place it on blocks high

enough to get drain plug over drain pan.

Always wear safety gog-

gles when servicing the

hydraulic system.

Summary of Contents for G0812

Page 84: ......