-54-

Model G0812 (Mfd. Since 2/16)

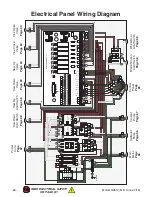

The Model G0812 has a blade brush to help keep

metal chips off the blade wheels. It will wear over

time and require re-adjustment when it no longer

makes proper contact with the blade. Eventually

the brush will require replacement. This is con-

sidered a normal wear item and is not covered by

warranty.

Tool Needed

Qty

Open-End Wrench 14mm .................................. 1

To adjust blade brush:

1. DISCONNECT MACHINE FROM POWER!

2. Using hex nut shown in Figure 80, adjust

blade brush so blade extends

1

⁄

8

" into bristles

of brush.

Blade Brush

Figure 80. Adjusting brush adjustment hex nut.

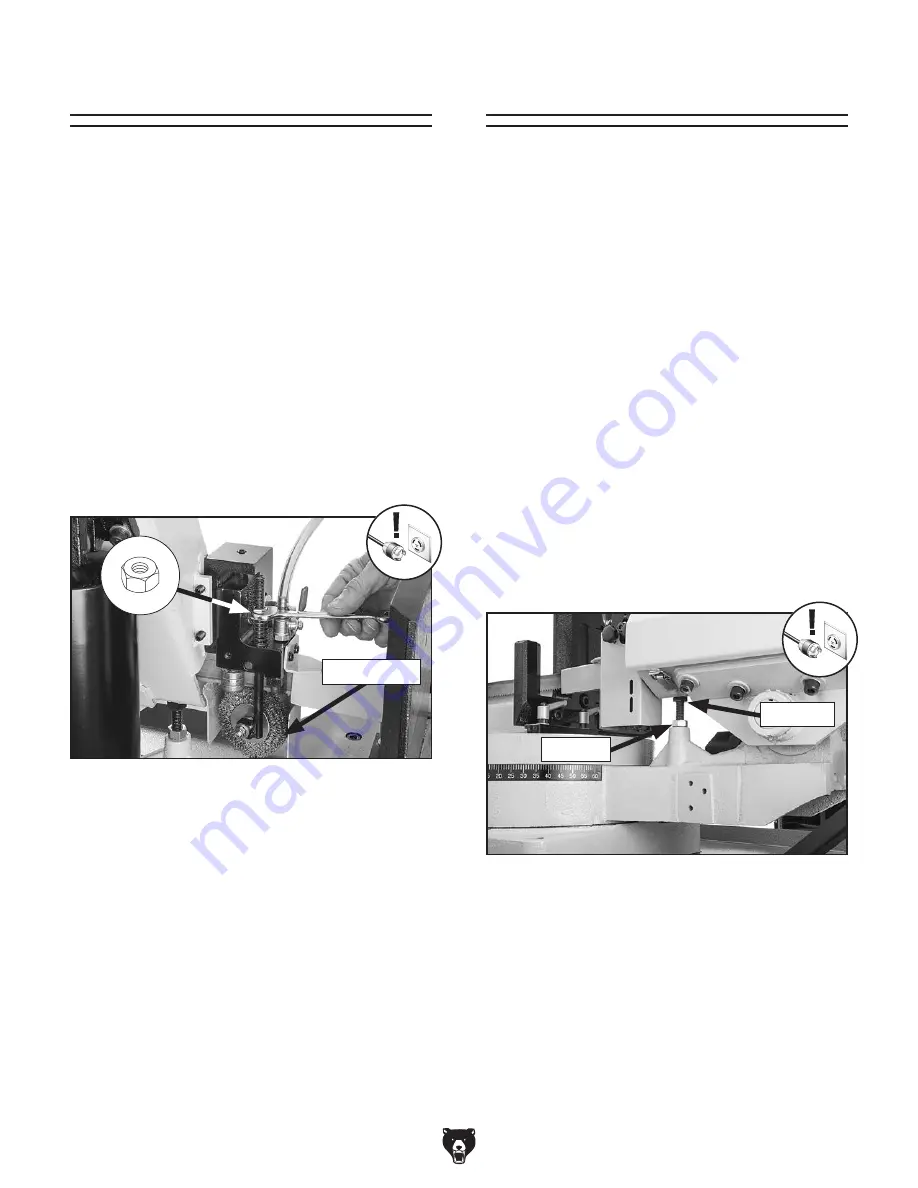

The Model G0812 has an adjustable stop bolt to

help support the headstock at the bottom of its

travel. If the blade does not travel far enough to

complete the cut or hits the table, this bolt will

have to be adjusted.

Tool Needed

Qty

Open-End Wrench 19mm .................................. 1

Downfeed Stop Bolt

To adjust downfeed stop bolt:

1. Without starting blade, lower headstock all the

way. When headstock stops, blade should be

just below table, but not contacting it.

— If blade contacts table, raise headstock

enough so blade is just below surface.

2. DISCONNECT MACHINE FROM POWER!

3. Adjust downfeed stop bolt and jam nut shown

in

Figure 81, so they contact bottom of head-

stock.

Figure 81. Downfeed stop bolt and jam nut

location.

Stop Bolt

4. Tighten jam nut against base to prevent stop

bolt from loosening during use.

Blade Brush

Jam Nut

Summary of Contents for G0812

Page 84: ......