-42-

Model G0815 (Mfd. Since 09/18)

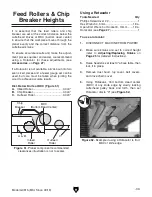

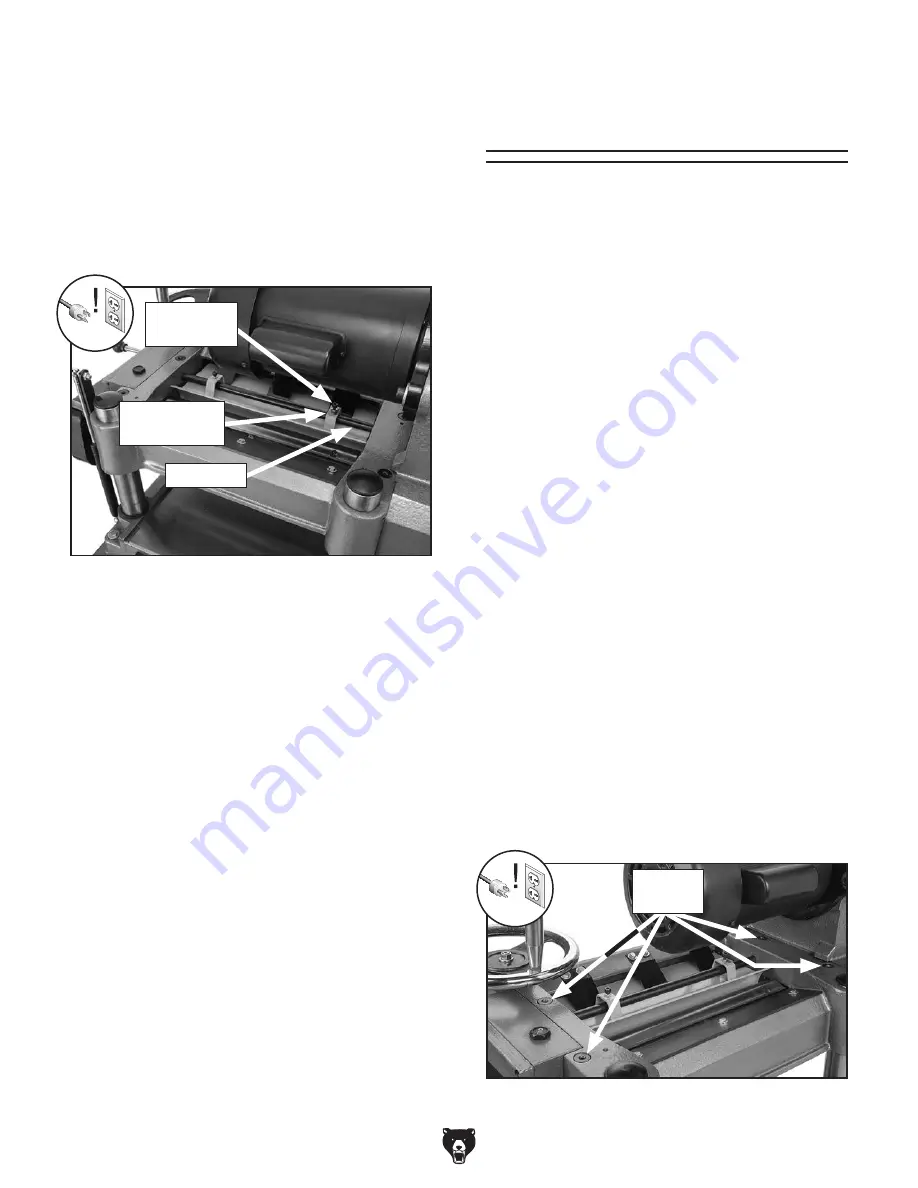

12. Repeat Steps 10–11 with outfeed roller, only

adjust the gaps to 0.020".

13. Loosen jam nuts and cap screws on each

side of chip breaker (see

Figure 57).

14. Using a feeler gauge, adjust cap screw so

it is 0.040" from cross bar (see

Figure 57),

then tighten jam nut. Repeat on other side of

chip breaker.

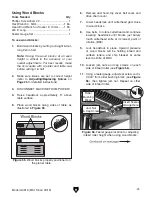

Adjusting Roller

Spring Tension

The infeed and outfeed rollers keep the workpiece

moving through the planer. There are springs that

exert downward pressure on the rollers while still

allowing them to raise with an uneven workpiece

surface. Proper roller spring tension is crucial to

keep the workpiece moving through the planer

during operation.

Roller spring tension will vary depending upon the

type of wood you are planing. When adjusting the

roller spring tension keep the following in mind:

•

If you are planing milled lumber with a rela-

tively consistent surface, use less spring ten-

sion.

•

If you are planing rough lumber with incon-

sistent surfaces, use greater spring tension

to keep the stock moving through the planer.

•

If the workpiece consistently stops feeding

during operation, the roller spring tension

may need to be increased.

Tools Needed

Qty

Hex Wrench 6mm .............................................. 1

To adjust roller spring tension:

1. DISCONNECT MACHINE FROM POWER!

2. Rotate tension screws clockwise to increase

tension, and counterclockwise to decrease

tension (see

Figure 58).

Figure 57. Feeler gauge location for adjusting

chip breaker height when using wood blocks.

Insert Feeler

Gauge Here

Cross Bar

15. Re-install belt cover, top cover, drive chain

cover, and dust hood.

Cap Screw

& Jam Nut

Figure 58. Roller spring tension adjustment

screws.

Tension

Screws

Summary of Contents for G0815

Page 56: ......