Model G0815 (Mfd. Since 09/18)

-43-

Positioning Chip

Deflector

Chip Deflector Gap Setting .....................

1

⁄

16

"–

1

⁄

8

"

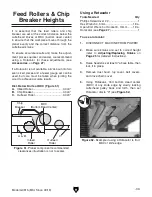

When properly distanced from the cutterhead, the

chip deflector directs the chips into the dust hood,

and keeps them from falling onto the outfeed roller

and being pressed into the workpiece.

Tools Needed

Qty

Phillips Screwdriver #2 ...................................... 1

Hex Wrench 5mm .............................................. 1

Open-End Wrench or Socket 10mm ................. 1

Fine Ruler or Calipers ....................................... 1

To adjust chip deflector gap:

1. DISCONNECT MACHINE FROM POWER!

2. Remove dust hood, top cover, and belt

covers.

3. Use cutterhead pulley to rotate cutterhead

until a knife reaches closest distance to chip

deflector (see

Figure 59), then measure dis-

tance between knife and chip deflector.

Anti-Kickback

Fingers

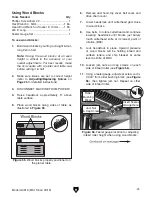

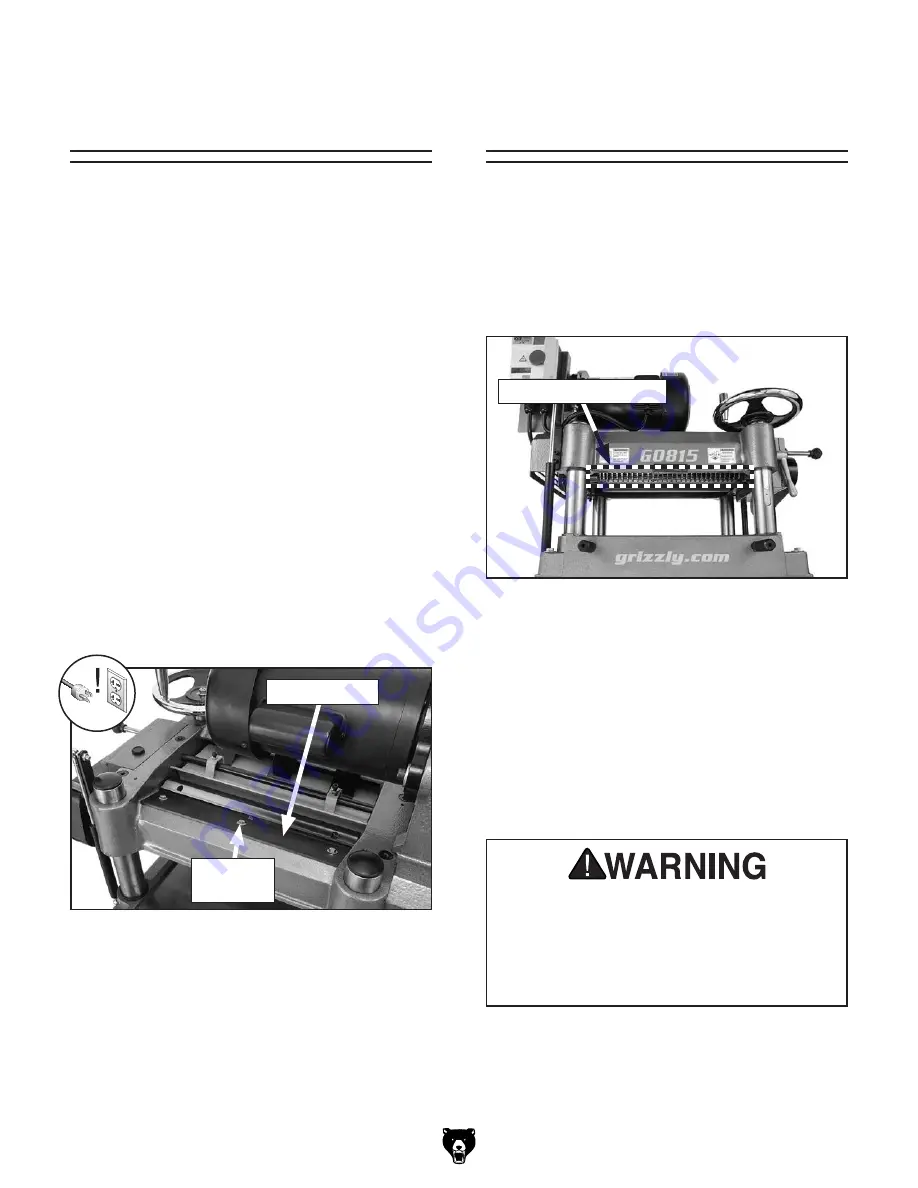

The anti-kickback fingers are an important safety

feature of your planer. The fingers hang from a rod

suspended across the head casting and in front

of the infeed roller, as shown in

Figure 60. This

design allows the workpiece to easily enter the

planer but reduces the risk of kickback by digging

into the workpiece if it moves backward.

Figure 60. Anti-kickback fingers.

Anti-Kickback Fingers

Check the anti-kickback fingers regularly to ensure

they swing freely and easily. If the fingers do not

swing freely and easily, first clean them with a

wood resin solvent, then inspect them for dam-

age. If any of the fingers are damaged, the device

must be replaced before using the machine.

Do not apply oil or other lubricants to the anti-

kickback fingers that will attract dust and restrict

free movement of the fingers.

Proper operation of anti-kickback fingers

is critical for safe operation of this planer.

DO NOT operate planer if anti-kickback

fingers are not operating correctly. Failure

to heed this warning could result in serious

personal injury.

Figure 59. Chip deflector and securing flange

bolts.

Chip Deflector

4. If distance measured in Step 3 is not

1

⁄

16

"–

1

⁄

8

",

then loosen flange screws that secure chip

deflector and adjust gap to

1

⁄

16

"–

1

⁄

8

".

5. Retighten flange screws, then replace belt

covers, top cover, and dust hood.

Hex Bolts

(1 of 3)

Summary of Contents for G0815

Page 56: ......