-28-

Model G0842 (Mfd. Since 04/18)

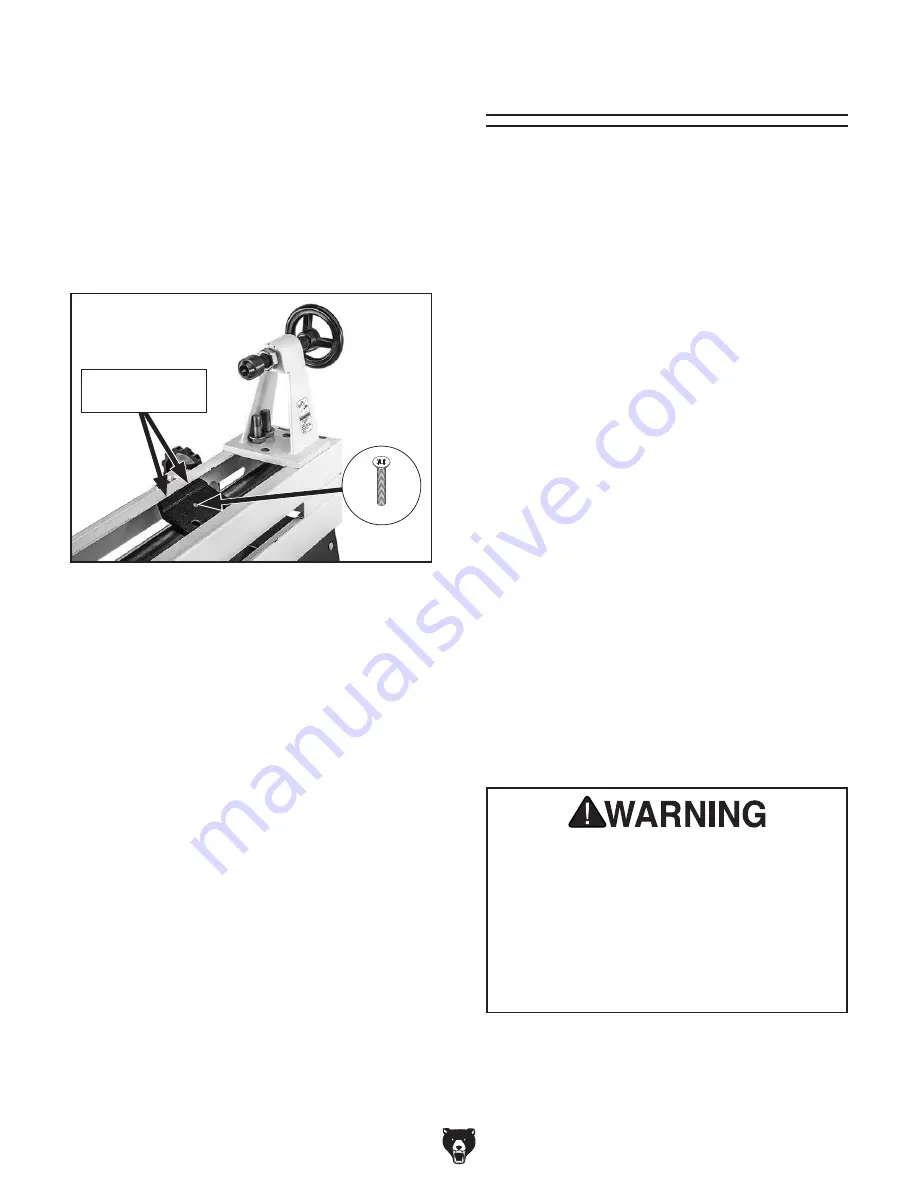

Removing Tailstock

Re-installing Tailstock

1. place clamping plate halves (figure 32)

under bedway in location where tailstock is

needed for desired operation, then secure

halves with (2) flat head screws.

2. re-install tailstock on clamping plate using

clamp bolts and flat washers from

Step 1 of

Removing Tailstock. Check to make sure

tailstock slides smoothly along bedway.

1. loosen tailstock clamp bolts shown in

figure 31 on Page 27, remove clamping

plate, clamp bolts, and flat washers from

tailstock, then move tailstock out of the way.

2. remove (2) flat head screws that secure

clamping plate halves together (see

figure

32), then remove plate halves and tailstock

from bed.

figure 32. Clamping plate halves.

x 2

Clamping plate

halves

Adjusting Tool Rest

the tool rest assembly consists of two compo-

nents: the tool rest base (or banjo) and the tool

rest. the tool rest base moves forward/backward

and left/right along the length of the lathe bed.

the tool rest rotates and moves up and down in

the tool rest base. locks for both components

allow you to secure the tool rest in position after

making these adjustments.

When adjusting the tool rest, position it as close

as possible to the workpiece without actually

touching it. this maximizes support where the

cutting occurs and minimizes leverage, reducing

the risk of injury if a "catch" occurs.

Many woodturners typically set the height of the

tool rest

1

⁄

8

" above or below the centerline of the

workpiece, depending on their height, the type

of tool they're using, and the type of operation

they're performing.

As a rule of thumb: For most (spindle) turning

operations, the cutting tool should contact the

workpiece slightly above centerline. For most

inside (bowl) turning operations, the cutting tool

should contact the workpiece slightly below

centerline.

Keeping all these factors in mind, your main goal

when adjusting the tool rest should be to provide

maximum support for the type of tool being used,

in a position that is safe and comfortable for you.

improperly supported or positioned cutting

tools can "catch" on workpiece, ejecting

tool from your hands with great force. To

reduce this risk, always ensure tool rest is

properly positioned for each type of opera-

tion, cutting tool is firmly supported against

tool rest bEfORE cutting, and cutting tool

is properly positioned to cut at the correct

angle for tool and operation type.

Summary of Contents for G0842

Page 56: ......