Model G0842 (Mfd. Since 04/18)

-41-

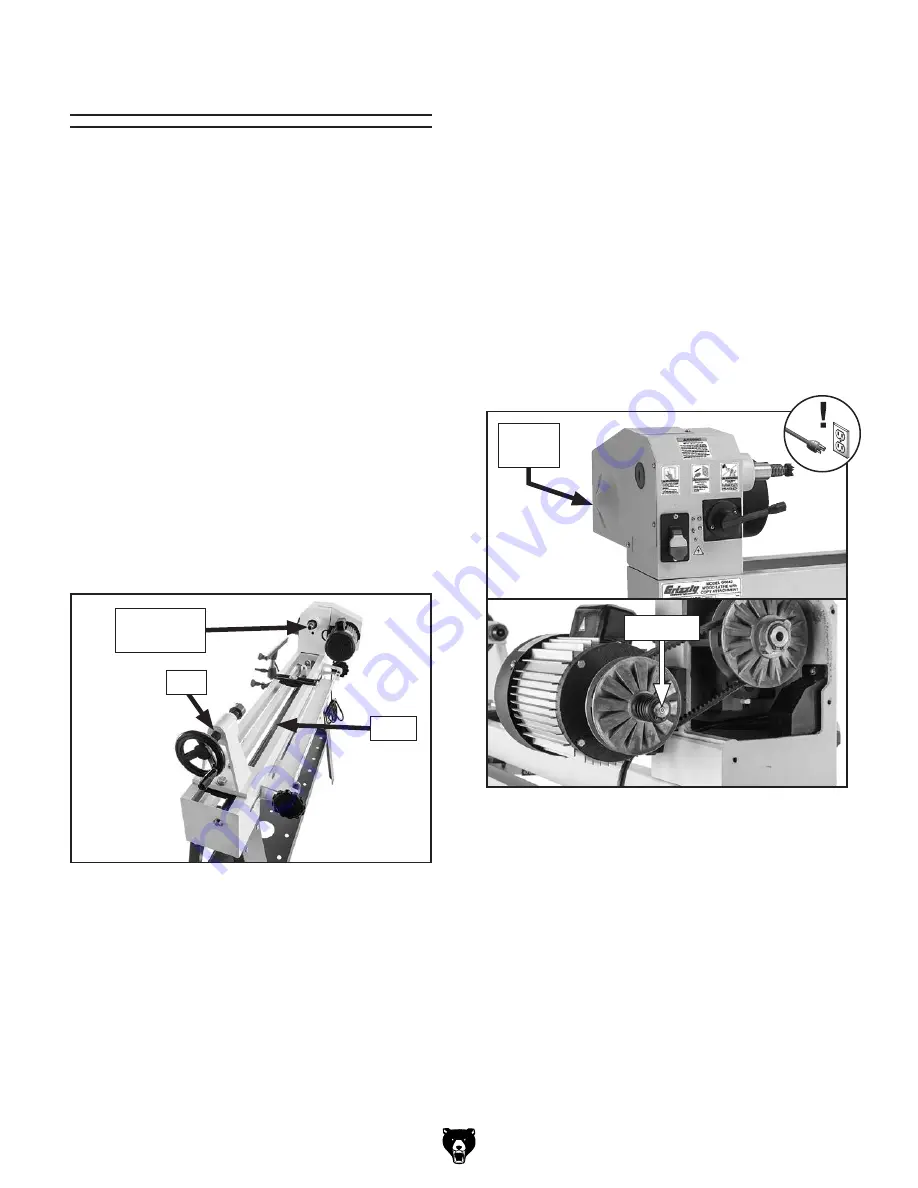

Motor Shaft Lubrication

Lubrication

the motor shaft must be properly lubricated

to ensure the variable-speed pulley assembly

can open and close smoothly when adjusted.

any common machine oil is acceptable for this

purpose, but we recommend using a "dry" type

lubricant, such as grizzly model g2545 or g4682,

to avoid attracting dust and prevent a build-up of

grime.

To lubricate motor shaft:

1. diSConnECt MaChinE FroM poWEr!

2. remove belt cover shown in figure 60 to

access motor shaft ball oiler.

3. push tip of oil can nozzle against ball oiler,

then pump can once or twice. alternatively,

if using a spray-type lubricant, place the end

of the straw against the ball oiler and give it a

quick squirt. do not over-lubricate.

4. turn machine ON and while remaining a safe

distance from the V-belt, run for approxi-

mately one minute. pull spindle speed shift

lever out and move and rotate left to right to

distribute oil.

5. turn machine OFF and re-install belt cover.

figure 60. location to access ball oiler.

Belt

Cover

Ball oiler

all bearings on this lathe are lubricated and per-

manently sealed at the factory, and do not need

additional lubrication.

Wipe a lightly oiled shop rag on the outside of the

headstock spindle (see

figure 59). do not allow

any oil to get on the inside mating surfaces of the

spindle.

use the tailstock handwheel to extend the quill

out to the furthest position and apply a thin coat

of dry lube, such as grizzly Model g4682 (refer

to

Cleaning and Protecting on Page 40) to the

outside of the quill (see

figure 59). do not allow

any oil or grease to get on the inside mating sur-

faces of the quill.

use mineral spirts and a shop rag to clean the

central shaft (see

figure 59) that runs the length

of the lathe. When dry, use apply a thin coat of

dry lube to the shaft and rack teeth on bottom of

the shaft.

figure 59. lubrication locations.

Shaft

Quill

headstock

Spindle

Summary of Contents for G0842

Page 56: ......