-22-

Model G0843P (Mfd. Since 11/17)

Sander Operation

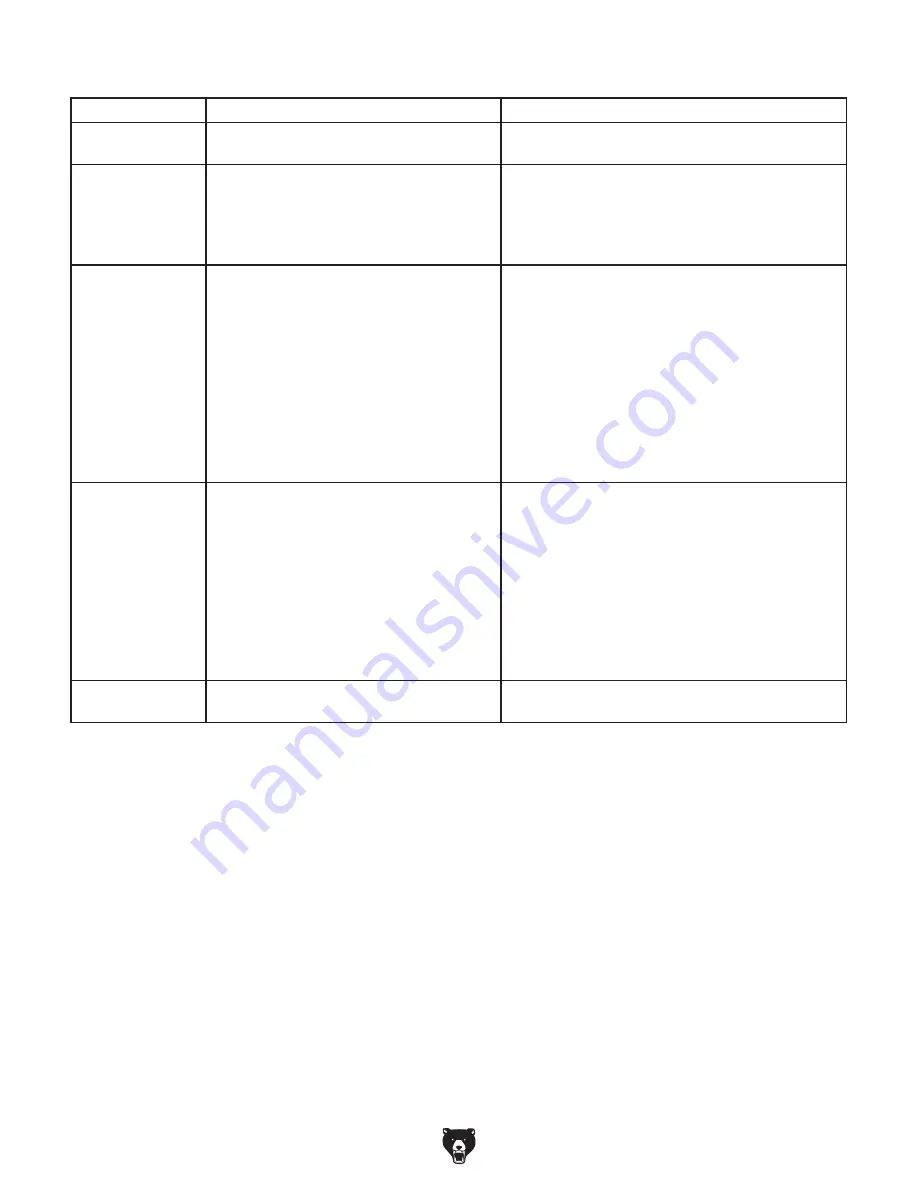

Symptom

Possible Cause

Possible Solution

Miter bar binds in

miter slot.

1. Miter slot dirty or gummed up.

1. Carefully clean miter slot with mineral spirits or

resin-dissolving cleaner.

Workpiece angle

incorrect or out of

square.

1. Miter slot not parallel with face of sanding

disc.

2. Table tilt not calibrated correctly.

3. Miter gauge not perpendicular to face of

sanding disc.

1. Set table gap and parallelism (

Page 23).

2. Calibrate table tilt. (

Page 24).

3. Calibrate miter gauge (

Page 24).

Sandpaper clogs

quickly or burns.

1. Sanding disc grit too fine for job.

2. Workpiece too moist.

3. Sanding pressure/depth too aggressive.

4. Paint, varnish, pitch, or other coating is

loading up sanding disc.

5. Sanding soft workpiece.

6. Work held still for too long.

1. Replace with coarser grit sanding disc (

Page 16).

2. Make sure moisture content is below 20%.

3. Reduce sanding pressure/depth, or install coarser

grit sanding disc (

Page 16).

4. Replace with coarser grit sanding disc (

Page 16), or

strip coating off before sanding.

5. Use different stock, or, accept characteristics of

stock and plan on cleaning/replacing sanding discs

frequently.

6. Move workpiece more frequently across sanding

disc (

Page 17).

Glossy spots, burn-

ing, or streaks on

workpiece.

1. Sanding disc too fine for the desired finish.

2. Work held still for too long.

3. Workpiece is too moist.

4. Sanding stock with high residue.

5. Worn sanding disc.

6. Sanding pressure too aggressive.

1. Replace with coarser grit sanding disc (

Page 16).

2. Move workpiece more frequently across sanding

disc (

Page 17).

3. Make sure moisture content is below 20%.

4. Use different stock, or, accept characteristics of

stock and plan on cleaning/replacing sanding discs

frequently.

5. Replace sanding disc (

Page 16).

6. Reduce sanding pressure, or install coarser

grit sanding disc (

Page 16).

Abrasive rubs off

the disc easily.

1. Sanding disc has been stored in an

incorrect environment.

1. Replace; store sanding discs away from extremely

dry, hot, or damp conditions.