Model G0844 (Mfd. Since 2/18)

-27-

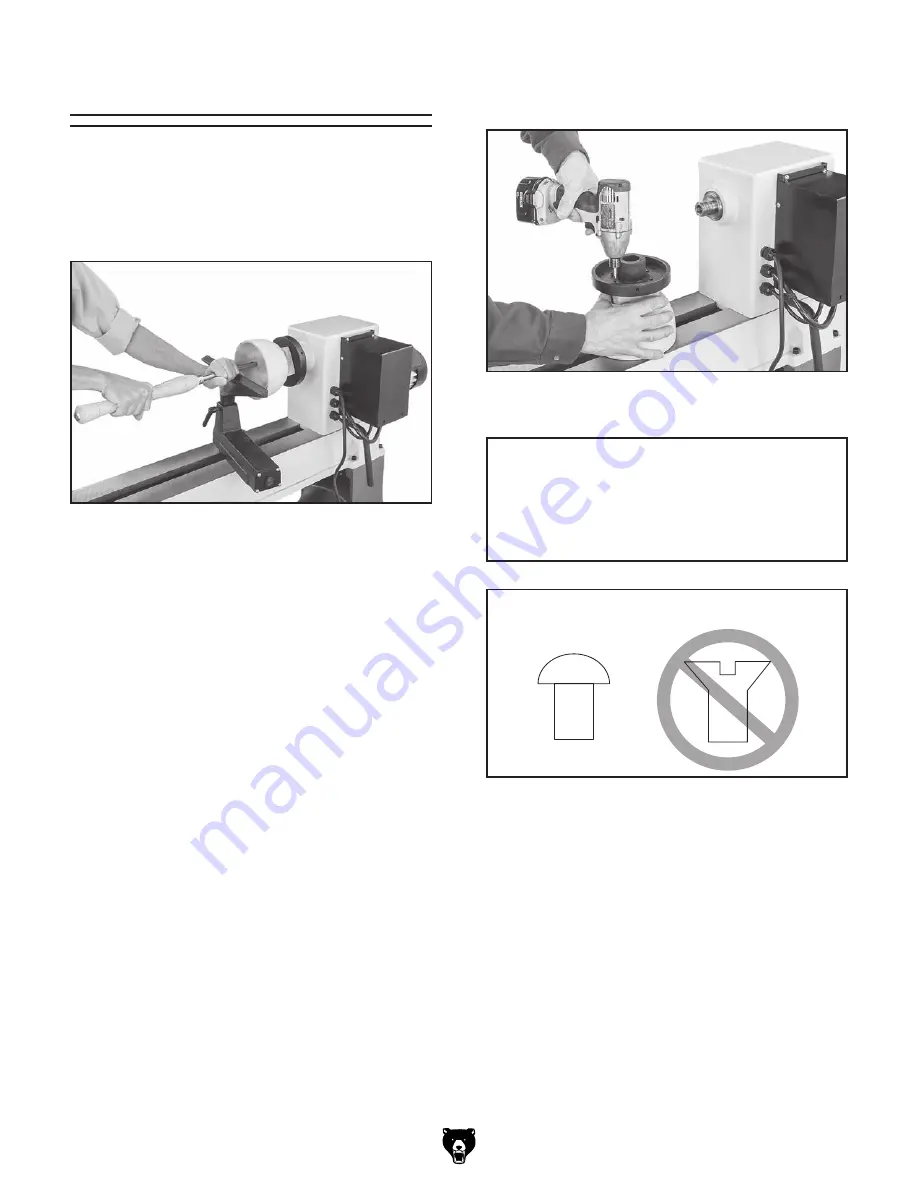

Faceplate Turning

Faceplate turning is when a workpiece is mounted

to the faceplate, which is then mounted to the

headstock spindle, as shown in

Figure 30. This

type of turning is usually done with open-faced

workpieces like bowls or plates.

Figure 30. Typical faceplate turning operation.

Figure 31. Typical attachment of faceplate to

workpiece.

2. Center faceplate on workpiece and attach it

(see

Figure 31) with wood screws.

NOTICE

Only use screws with non-tapered heads

(see Figure 32) to attach faceplate to the

workpiece. Screws with tapered heads can

split faceplate or snap off during operation.

Correct

Incorrect

Figure 32. Correct and incorrect screw types.

3. Thread and secure faceplate onto headstock

spindle (refer to

Installing Faceplate on

Page 22).

— If wood screws cannot be placed in

workpiece, faceplate can be mounted to

a backing block attached to workpiece

(see

Mounting Workpiece on Backing

Block).

Mounting Workpiece on Faceplate

Items Needed

Qty

Precision Ruler .................................................. 1

Wood Screws .................................................... 1

Drill ................................................................... 1

Tablesaw/Bandsaw ............................................ 1

To mount workpiece on faceplate:

1. Mark workpiece center in same manner as

described in

Spindle Turning (see Page 25).

Note: Cut off corners of workpiece to make it

as close to "round" as possible, as described

in

Spindle Turning, Step 5 (see Page 25).

Summary of Contents for G0844

Page 48: ......