-28-

Model G0844 (Mfd. Since 2/18)

To mount workpiece on backing block:

1. Make backing block from a suitable size

piece of scrap wood.

Note:

Faces of backing block must be flat and

parallel with each other, or uneven surfaces

will cause workpiece to spin eccentrically,

causing unnecessary vibration and runout. It

is best to mount backing block to faceplate

and turn other surface flat prior to mounting.

2. Locate and mark center of workpiece and

backing block.

3. Drill a

1

⁄

4

" hole through center of backing block.

4. Look through hole in backing block to line

up center with workpiece, and then glue and

clamp backing block to workpiece.

Note: Allow glue to cure according to manu-

facturer's instructions.

5. Follow Steps 1–3 under Mounting

Workpiece on Faceplate (see Page 27) to

attach backing block to faceplate.

Mounting Workpiece on Backing

Block

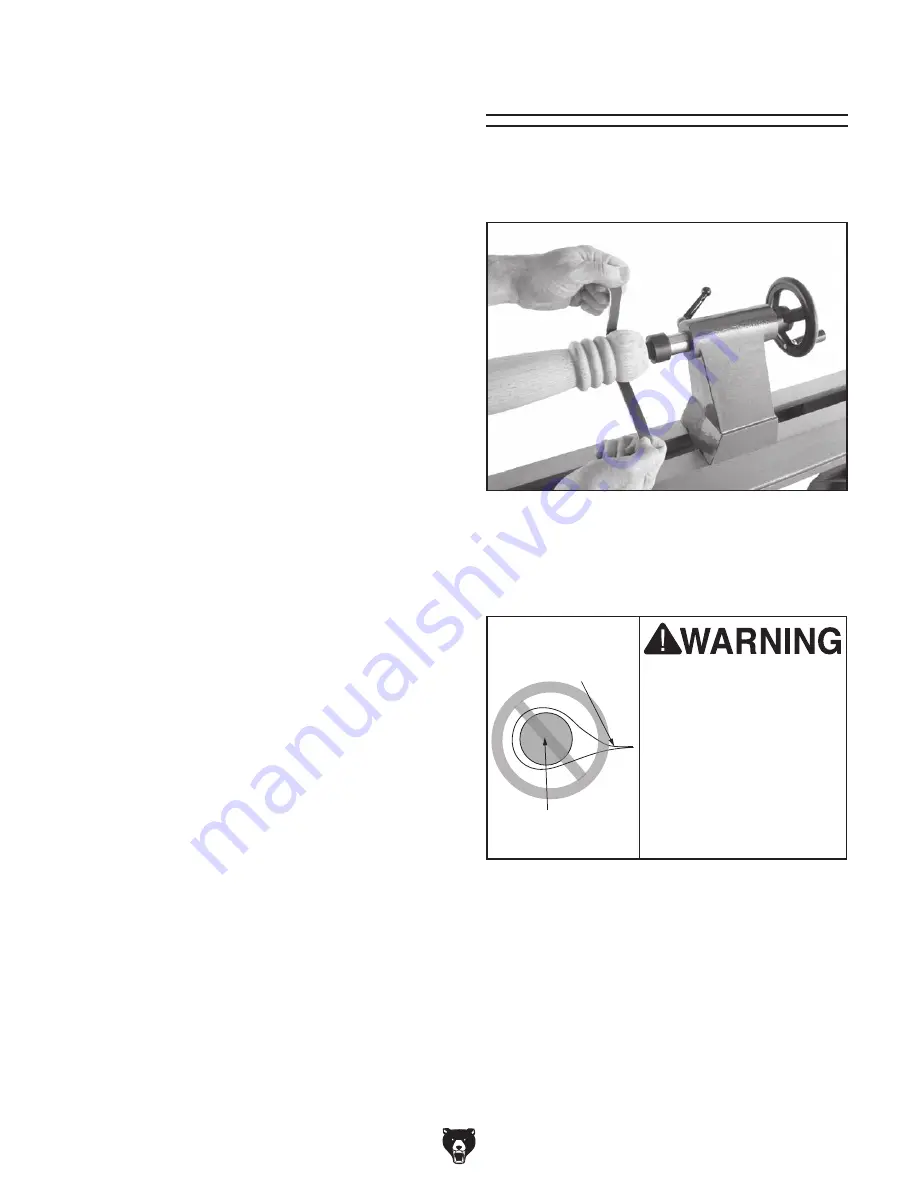

Sanding/Finishing

After the turning operations are complete, the

workpiece can be sanded and finished before

removing it from the lathe, as shown in

Figure 33.

Figure 33. Typical sanding operation.

Note: Whenever sanding or finishing, move the

tool rest holder out of the way to increase per-

sonal safety and gain adequate working room.

Wrapping sandpa-

per completely around

workpiece could pull

your hands into mov-

ing workpiece and may

cause serious injury.

Never wrap sandpa-

per or finishing materi-

als completely around

workpiece.

Sandpaper

Workpiece

Items Needed

Qty

Piece of Scrap Wood......................................... 1

Precision Ruler .................................................. 1

Drill Bit

1

⁄

4

" .......................................................... 1

Glue ................................................... As Needed

Clamp ................................................................ 1

Summary of Contents for G0844

Page 48: ......