Model G0844 (Mfd. Since 2/18)

-35-

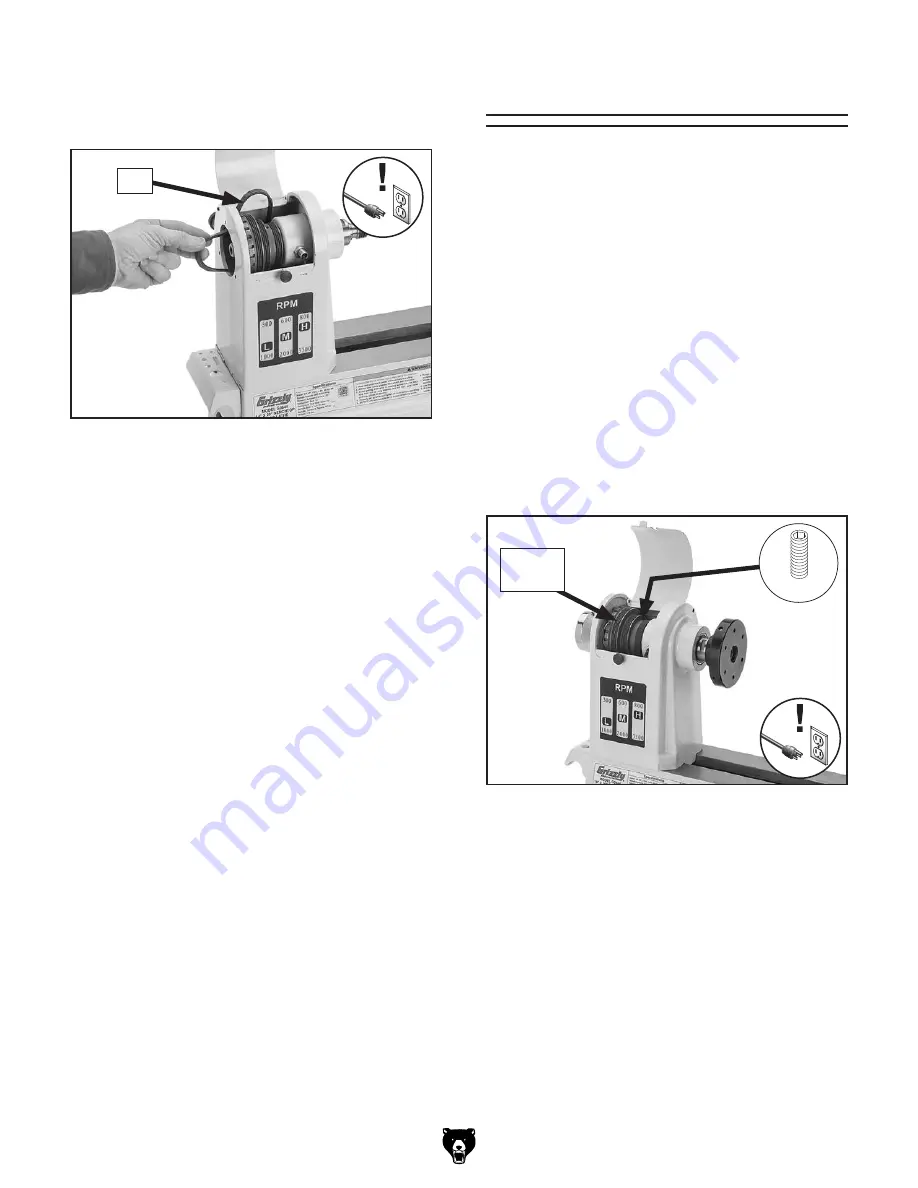

6. Insert new belt through lower opening, and

pull it around end of spindle onto pulley

(see

Figure 44).

The motor and spindle pulleys are aligned at the

factory and should not require any adjustment. If

they become misaligned over time, it is important

that they be re-aligned in order to extend belt

life and maximize the transfer of power from the

motor to the spindle.

Tool Needed

Qty

Hex Wrench 3mm .............................................. 1

To align motor and spindle pulleys:

1. DISCONNECT MACHINE FROM POWER!

2. Open front access cover.

3. Loosen (2) set screws on spindle pulley

(see

Figure 45).

4. Slide spindle pulley into alignment with motor

pulley.

Note: When pulleys are properly aligned,

there should be no unusual or pulsing sounds

coming from the belt.

5. Tighten set screws.

Figure 45. Location of spindle pulley and set

screws.

Aligning Pulleys

Spindle

Pulley

7. Re-install end cover and headstock spindle

handwheel.

8. Loosely install belt on inner or outermost

motor pulley position.

9. Loosen belt-tension lock handle, move belt-

tension lever down to tension belt, then

tighten belt-tension lock handle.

10. Follow Step 4 in the Tensioning Belt proce-

dure to set belt tension.

11. Re-install side access cover and close front

access cover.

Figure 44. Installing belt onto spindle pulley.

1 of 2

Belt

Summary of Contents for G0844

Page 48: ......