Model G0853 (Mfd. Since 07/18)

-105-

READ ELECTRICAL SAFETY

ON PAGE 100!

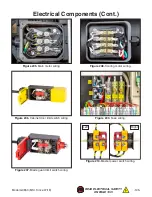

Figure 206. Cabinet door limit switch wiring.

Figure 205. Main motor wiring.

Figure 208. Scoring motor wiring.

Figure 207. Blade guard limit switch wiring.

Electrical Components (Cont.)

Figure 209. Fuse wiring.

Figure 210. Master power switch wiring.

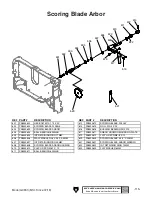

Left

Right

Summary of Contents for G0853

Page 24: ...22 Model G0853 Mfd Since 07 18 5mm Hardware Recognition Chart...

Page 140: ......