-32-

Model G0879 (Mfd. Since 6/19)

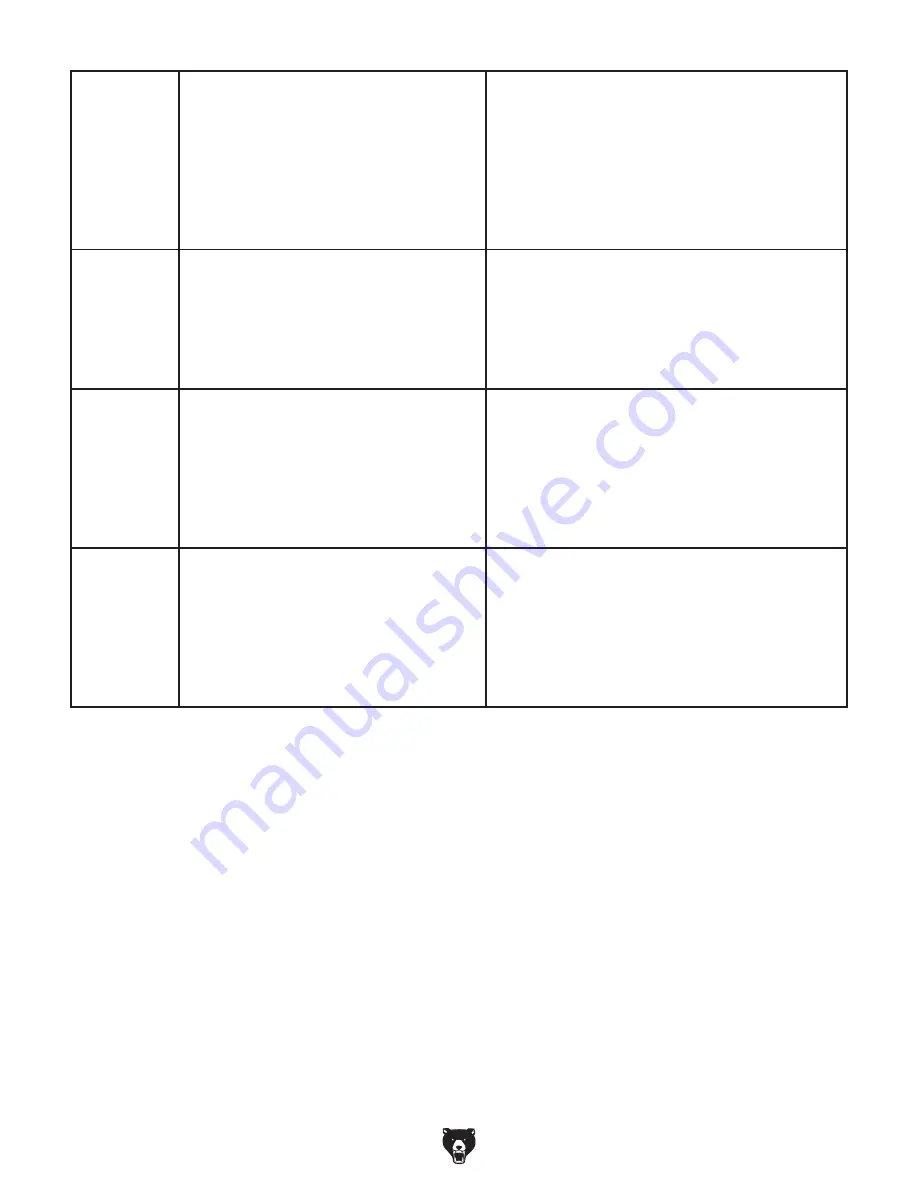

Difficulty/

inability to

properly start/

arc a weld.

1. Improperly cleaned workpiece/ wrong type of

material.

2. Ground clamp not connected to workpiece/

too far from weld location/bad ground

connection.

3. Machine settings incorrect for workpiece.

4. Residue build up at end of wire insulates

electrode and makes starting arc difficult.

1. Clean workpiece/ use correct type of material.

2. Connect ground clamp close to workpiece. Make

sure ground clamp is connected/terminals are clean

(

Page 13).

3. Adjust machine settings to be appropriate for

workpiece (

Page 25).

4. Break/cut tip of wire off before beginning weld.

Burning holes

in workpiece.

1. Material too thin for welding operation.

2. Welding amperage output too high.

3. Wire speed too high.

4. Welding torch moved too slow.

5. Contact tip to workpiece distance to long.

1. Use thicker material. Not recommended to weld

material thinner than

1

⁄

16

" steel with G0879 (

Page 7).

2. Lower amperage output.

3. Reduce wire speed.

4. Increase welding torch travel speed.

5. Maintain contact tip to workpiece distance of

3

⁄

16

"-

1

⁄

4

"

(

Page 24).

Lack of weld

penetration.

1. Improperly cleaned workpiece/ wrong type

of material/ material too thick for welding

operation.

2. Welding output amperage too low.

3. Wire speed too slow.

4. Welding torch moved too quick.

5. Contact tip to workpiece distance to short.

1. Clean workpiece/ use correct type of material/

maximum material thickness for G0879 is

3

⁄

16

" steel

(

Page 7).

2. Increase amperage output.

3. Increase wire speed.

4. Decrease welding torch travel speed.

5. Maintain contact tip to workpiece distance of

3

⁄

16

"-

1

⁄

4

"

(

Page 24).

Unable to

maintain

constant arc;

excessive

spatter.

1. Contact tip to workpiece distance too long.

2. Ground clamp not connected to workpiece/

too far from weld location/bad ground

connection.

3. Welding output amperage too high.

4. Wire speed too high.

5. Welding torch moved too slow.

1. Maintain appropriate contact tip to workpiece distance

throughout entire weld.

2. Connect ground clamp close to workpiece. Make

sure ground clamp is connected/terminals are clean

(

Page 13).

3. Lower amperage output.

4. Reduce wire speed.

5. Increase welding torch travel speed.

Summary of Contents for G0879

Page 36: ......