-32-

Model G0887 (Mfd. Since 01/19)

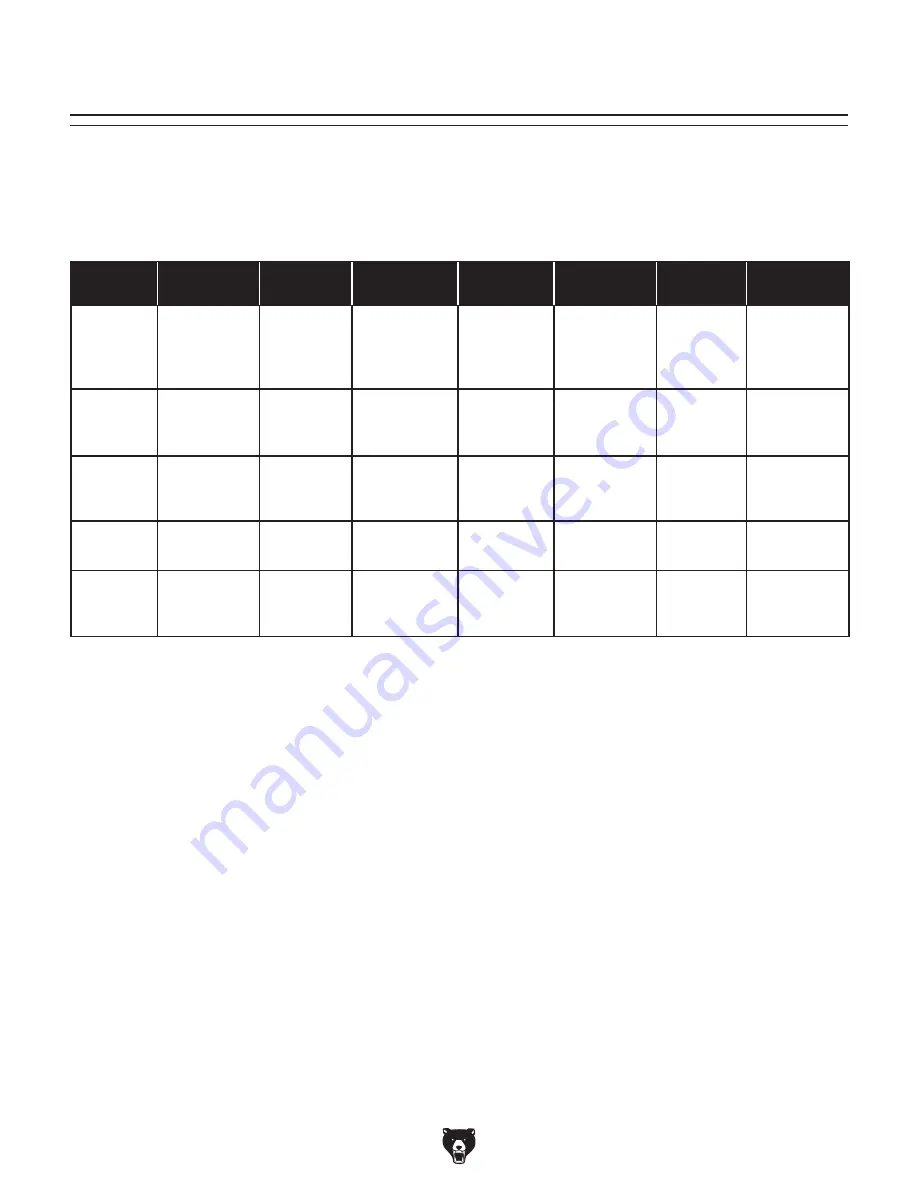

The chart in

Figure 26 offers blade speed guidelines for various metals, given in feet per minute (FPM)

and meters per minute (M/Min). Choose the closest available speed on the machine, then adjust the feed

rate as necessary, using the appearance of the chips produced as a guide. Refer to the

Chip Inspection

Chart that follows for recommendations on adjusting feed rate or blade speed based on the appearance of

the chips produced.

Blade Speed Chart

Figure 26. Blade speed chart.

Material Speed FPM

(M/Min)

Material

Speed FPM

(M/Min)

Material

Speed FPM

(M/Min)

Material

Speed FPM

(M/Min)

Carbon

Steel

196~354

(60) (108)

Tool Steel

203

(62)

Alloy Steel

111~321

(34) (98)

Free

Machining

Stainless

Steel

150~203

(46) (62)

Angle

Steel

180~220

(54) (67)

High-

Speed

Tool Steel

75~118

(25) (36)

Mold Steel

246

(75)

Gray Cast

Iron

108~225

(33) (75)

Thin Tube

180~220

(54) (67)

Cold-Work

Tool Steel

95~213

(29) (65)

Water-

Hardened

Tool Steel

242

(74)

Ductile

Austenitic

Cast Iron

65~85

(20) (26)

Aluminum

Alloy

220~534

(67) (163)

Hot-Work

Tool Steel

203

(62)

Stainless

Steel

85

(26)

Malleable

Cast Iron

321

(98)

Copper

Alloy

229~482

(70) (147)

Oil-

Hardened

Tool Steel

203~213

(62) (65)

CR

Stainless

Steel

85~203

(26) (62)

Plastics &

Lumber

220

(67)

Summary of Contents for G0887

Page 108: ......