-36-

Model G0887 (Mfd. Since 01/19)

— If there is just enough space to fit fin-

gernail, then blade tracking is properly

adjusted. Continue to

Step 3.

— If there is too little or too much space to

fit fingernail, then blade tracking must be

properly adjusted before tensioning blade.

(Refer to

Adjusting Blade Tracking on

Page 68.)

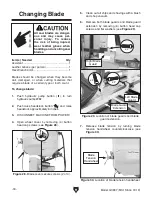

4. Remove blade guard extension (see

Figure 35).

Figure 35. Blade guard extension location.

5. Loosen adjustable handle on left blade guide

arm and move arm as far left as it will go

(see

Figure 36). Tighten adjustable handle to

secure arm position.

Figure 36. Left blade guide adjustable handle.

Left Blade

Guide Arm

Adjustable

Handle

x 2

Blade Guard

Extension

Tensioning Blade

Proper blade tension is essential to avoid blade

vibration, twist, or slippage on the wheels. A cor-

rectly tensioned blade provides long blade life,

straight cuts, and efficient cutting.

The three major signs of incorrect blade tension

are: 1) The blade stalls in the cut and slips on the

wheels, 2) the blade frequently breaks, and 3) the

bandsaw does not make straight cuts.

The blade tension failure indicator light will illu-

minate and the control panel will beep (see

Identifying Failures on Page 40) if the bandsaw

is turned

ON and the tension is not set correctly.

Loosen blade tension at the end of each day

to prolong blade life.

To tension blade:

1. DISCONNECT MACHINE FROM POWER!

2. Open wheel cover by removing (4) button

head cap screws (see

Figure 34).

Figure 34. Wheel cover secure screws (2 of 4).

Tools Needed

Qty

Hex Wrench 4mm .............................................. 1

3. Perform quick blade tracking check by sliding

fingernail between end of blade and wheel

shoulder.

Summary of Contents for G0887

Page 108: ......