Model G0901 (Mfd. Since 09/19)

-23-

Tensioning Blade

A properly tensioned blade is essential for mak-

ing accurate cuts, maximizing blade life, and

making other bandsaw adjustments. However, a

properly tensioned blade will not compensate for

cutting problems caused by excessive feed rate,

hardness variations between workpieces, and

improper blade selection.

An over-tensioned blade increases the chance of

the blade breaking or wheel misalignment. Under-

tensioned blades wander excessively while cut-

ting and will not track properly during operation.

IMPORTANT: Always release blade tension when

storing machine. Storing the blade with high blade

tension for extended time period can deform

blade and weaken tensioning spring, reducing the

durability and accuracy of the machine.

Note: Relying on the indicator to set tension pro-

vides a quick and easy method of achieving safe,

operational blade tension. If more precision is

required, consider using a blade tensioning gauge

(see

Page 32).

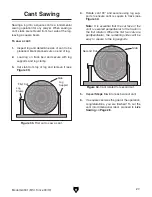

Figure 25. Blade tension indicator.

To tension blade:

1. Turn blade tension handle clockwise until

spring head is even with indicator bracket

(see

Figure 25).

Indicator

Bracket

Spring

Head

Installing Blade

1. DISCONNECT SPARK PLUG WIRE!

2. Open blade cover and support it on blade

cover latch (see

Figure 23).

Figure 23. Blade cover supported by blade

cover latch.

Blade Cover

Latch

Figure 24. Proper blade routing.

5. Close blade cover.

6. Adjust blade tension, then adjust guide roll-

ers (see

Tensioning Blade on this page and

Adjusting Guide Rollers on Page 24).

Guide

Roller

3. Hold blade from each side and position it in

front of wheels so blade teeth are facing front

of machine and pointing toward dust port.

4. Slide blade through slots in bottom of blade

housing and under guide rollers (see

Figure

24), then slide blade over each wheel.

Summary of Contents for G0901

Page 56: ......