-34-

Model G0901 (Mfd. Since 09/19)

SECTION 5: MAINTENANCE

For optimum performance from this machine, this

maintenance schedule must be strictly followed.

Ongoing

To minimize your risk of injury and maintain proper

machine operation, shut down the machine imme-

diately if you ever observe any of the items below,

and fix the problem before continuing operations:

•

Loose mounting bolts.

•

Dull or damaged saw blade.

•

Wood chip and sawdust buildup.

•

Low fuel and lubrication levels.

•

Damaged or worn guides rollers.

Monthly Check

•

V-belt tension, damage, or wear.

Schedule

Cleaning the Model G0901 is relatively easy.

Vacuum excess wood chips and sawdust, and

wipe off the remaining dust with a dry cloth. If any

resin has built up, use a resin dissolving cleaner

to remove it.

Cleaning &

Protecting

Most bearings on this machine, except for those

with grease fittings, are sealed and permanently

lubricated. Leave these bearings alone until they

need to be replaced. Do not lubricate them.

Apply light machine oil to the lift chain every 40

hours of use, prior to storage, or as needed. Clean

machine thoroughly before applying oil. The goal

is to achieve adequate lubrication. Too much lubri-

cation will attract dirt and sawdust.

Lubrication

Wipe clean and lubricate all grease fittings with two

pumps of high-temp bearing grease (see

Figure

53 on Page 33). Grease fittings should be lubri-

cated after approximately 160 hours of use.

Grease Fittings

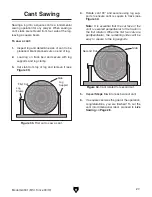

Figure 54. Left side grease fittings.

Grease

Fitting

Grease

Fitting

Grease

Fitting

Figure 55. Right side grease fittings.

Grease

Fitting

Grease

Fitting

Grease

Fitting

Engine

Follow Briggs & Stratton engine manual for engine

maintenance schedule. Refer to

Operations in

the engine manual for fuel and oil requirements.

Do not overfill fuel or oil.

Summary of Contents for G0901

Page 56: ......