Model G0901 (Mfd. Since 09/19)

-37-

Tensioning/

Replacing V-Belts

To ensure optimum power transmission from the

engine to the blade, the drive belt must be prop-

erly tensioned.

Tools Needed

Qty

Open-End Wrench 17mm .................................. 1

To check/adjust drive belt tension:

1. DISCONNECT SPARK PLUG WIRE!

2. Open blade cover and secure to blade cover

latch.

3. Inspect drive belt; if it is cracked, frayed, or

glazed, replace it (refer to

Page 38).

Checking/Adjusting Drive Belt Tension

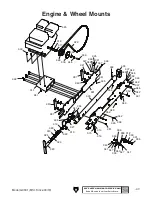

5. Loosen pulley bracket hex nut and belt ten-

sion hex nut (see

Figure 58).

6. Tighten/loosen belt tension bolt to adjust

tension pulley until drive belt is correctly ten-

sioned (see

Figure 58).

7. Tighten pulley bracket hex nut and belt ten-

sion hex nut (see

Figure 58).

Figure 58. Drive belt tension controls.

Tension

Pulley

Belt Tension

Bolt

Pulley

Bracket

Hex Nut

Belt Tension

Hex Nut

Figure 57. V-belt deflection.

Bandsaw

Wheel

Deflection

Motor

Wheel

The G0901 uses V-belts as tires on the blade

wheels. The drive belt transfers power from the

engine to the wheels. The blade and drive belt

must be tensioned properly to ensure proper

operation. It is essential that both drive belt and

follower belt are free of cracks, fraying, and wear.

V-belt condition and tension should be checked at

least every 3 months —more often if the sawmill is

used daily.

4. Check drive belt tension by applying moder-

ate pressure between pulleys (see

Figure

57).

— If deflection is approximately

1

⁄

4

", belt is

correctly tensioned and no adjustment is

necessary.

— If deflection is not approximately

1

⁄

4

", belt is

not correctly tensioned. Proceed to

Step 5.

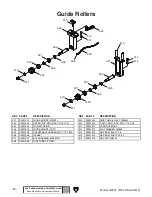

Figure 56. G0901 V-belts.

Follower Belt

Drive

Belt

Summary of Contents for G0901

Page 56: ......