HEAVY LIFT!

Straining or crushing injury

may occur from improperly

lifting machine or some of

its parts. To reduce this

risk, use a forklift (or other

lifting equipment) rated for

weight of this machine.

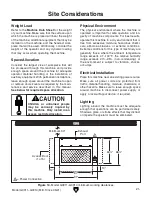

Figure 15. Adjustable foot components.

-22-

Model G0911–G0914 (Mfd. Since 05/21)

DO NOT attempt to lift or move this machine with-

out using the proper lifting equipment (such as a

forklift) or the necessary assistance from other

people. Each piece of lifting equipment must be

rated for

at least 2300 lbs. to support dynamic

loads that may be applied while lifting. Refer to

Needed for Setup on Page 18 for complete list

of needed equipment for setup and installation.

Verify location meets the following conditions:

•

Adequate ventilation so machine does not fill

an enclosed area with toxic fumes from cut-

ting certain types of materials.

•

Immediate access to auxiliary systems for

verifying operation and ease of maintenance.

To lift and place machine:

1. Using forklift and assistance from an addi-

tional person, move crate to machine work

site location.

2. Remove crate top and sides, components

inside crate, and blocks near machine base.

Note: To reduce weight, remove honey-

comb table, blade table, and any loose parts

from cabinet. Table components are not

permanently mounted and require no tools to

remove or install.

3. Lift machine with forklift just enough to clear

pallet, then move pallet out of the way.

4. Lower machine and proceed to Leveling on

this page.

Lifting & Placing

Leveling machinery helps precision components

remain straight and flat during the lifespan of the

machine. The table of a machine may slowly twist

over time, causing inadequate workpiece cutting

and variations in engraving quality.

To level machine:

1. Place level on table and align to either X- or

Y-axis.

2. Loosen hex nut on each adjustable foot

threaded bolt, then rotate fixed nut until mea-

sured axis is level (see

Figure 15).

Note: Rotate fixed nut clockwise to raise

machine, and counterclockwise to lower

machine.

Leveling

3. Align level on table to opposite axis. Repeat

Step 2 as needed.

4. Tighten hex nut on each adjustable foot

threaded bolt against machine base to secure

position.

Fixed Nut

Foot Pad

Hex Nut

Threaded

Bolt

Summary of Contents for G0911

Page 100: ......