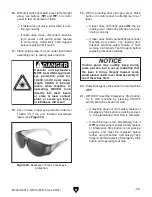

Figure 20. Air bubbles present in laser tube.

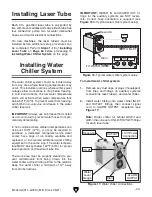

Figure 18. Water and air fittings for auxiliary

systems connections (G0911/G0912 shown).

Figure 19. Water level gauge location.

-24-

Model G0911–G0914 (Mfd. Since 05/21)

3. Connect opposite end of OUTLET hose to

auxiliary systems WATER IN

fitting (see

Figure 18).

4. Connect opposite end of INLET hose to

auxiliary systems WATER OUT fitting (see

Figure 18).

5. Connect signal cord to SIGNAL receptacle on

machine (see

Figure 18).

6. Fill water chiller reservoir with 1

1

⁄

2

gallons of

distilled water.

IMPORTANT: The cooling system requires

distilled water to prevent scaling and con-

taminant build-up. Water quality and effective

cooling directly contribute to the operational

life of the laser tube.

7. Connect power cord to 110V power connec-

tion on water chiller (see

Figure 19).

8. Connect water chiller system to power and

turn

ON. Allow water to cycle for one minute

and continue filling reservoir with distilled

water until water level is in green area on

water level gauge (see

Figure 19).

Note: Water chiller can be connected to aux-

iliary power connection on rear of machine.

9. Open laser tube access door and verify large

air bubbles have released from laser tube

(see

Figure 20).

Note: If needed, loosen laser tube saddle

straps then slowly rotate laser tube while

slightly raising tube at cathode-end to release

persistent air bubbles.

Large Air

Bubbles

Water

Level

Gauge

110V Power

Connection

Summary of Contents for G0911

Page 100: ......