Minimum CFM at Exhaust Port: 200 CFM

DO NOT confuse this CFM recommendation

with the rating of the fume extractor. To deter-

mine the CFM at the exhaust port, you must

consider these variables: (1) CFM rating of

the fume extractor, (2) hose type and length

between air filters (MERV 15+, HEPA, Carbon,

etc.) and the machine, (3) number of branches

or wyes, and (4) amount of other open lines

throughout the system. Explaining how to cal-

culate these variables is beyond the scope of

this manual. Consult an expert or purchase a

dedicated CNC laser "how-to" book.

If extraction outlet ducting is routed out-

side, install a metal screen on duct opening

to prevent invasive animals from nesting in

extraction system.

Grizzly Industrial recommends connecting

extraction fan to a dedicated power circuit

independent from the Model G0911–G0914

to prevent interrupting power.

Figure 23. Extraction fan inlet and outlet ports.

Upper Exhaust Port

Lower Exhaust Port

Exhaust Port Adapter

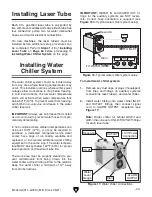

Figure 22. Installing exhaust port adapter.

-26-

Model G0911–G0914 (Mfd. Since 05/21)

3. Use (2) 6" hose clamps to connect and secure

one end of ducting to exhaust port adapter on

machine, then connect and secure other end

of ducting to inlet port of extraction fan (see

Figure 23).

4. Use (1) 6" hose clamp to connect and secure

remaining ducting to extraction fan outlet port

(see

Figure 23).

To install extraction fan:

1. Insert exhaust port adapter into upper and

lower exhaust ports on rear of machine and

secure with (1) 6" hose clamp on upper

exhaust port (see

Figure 22).

2. Place extraction fan, electrical cord, and

ducting in a location that prevents tripping

hazards, duct kinks, and abrasive damage.

Note: Ensure ducting is kept as straight as

possible for maximum efficiency.

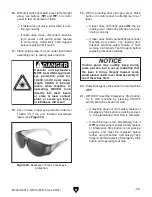

7. Connect extraction fan to an available 110V

grounded power source separate from Model

G0911–G0914 power connection circuit.

IMPORTANT:

Extraction fan has a high cur-

rent draw and may be required to operate

on separate circuit from the Model G0911–

G0914.

Always refer to a certified electrician

for electrical circuit requirements, if needed.

5. Route and connect ducting to fume extrac-

tor that utilizes a MERV 15+ or HEPA filter

(see

Additional Safety for Toxic Fumes

Generated by Laser Cutting on Page 15).

Secure ducting to fume extractor using (1) 6"

hose clamp.

6. Secure extraction fan in accessible location

where ducting can be removed and cleaned

during maintenance.

Inlet

Port

Outlet

Port

Summary of Contents for G0911

Page 100: ......