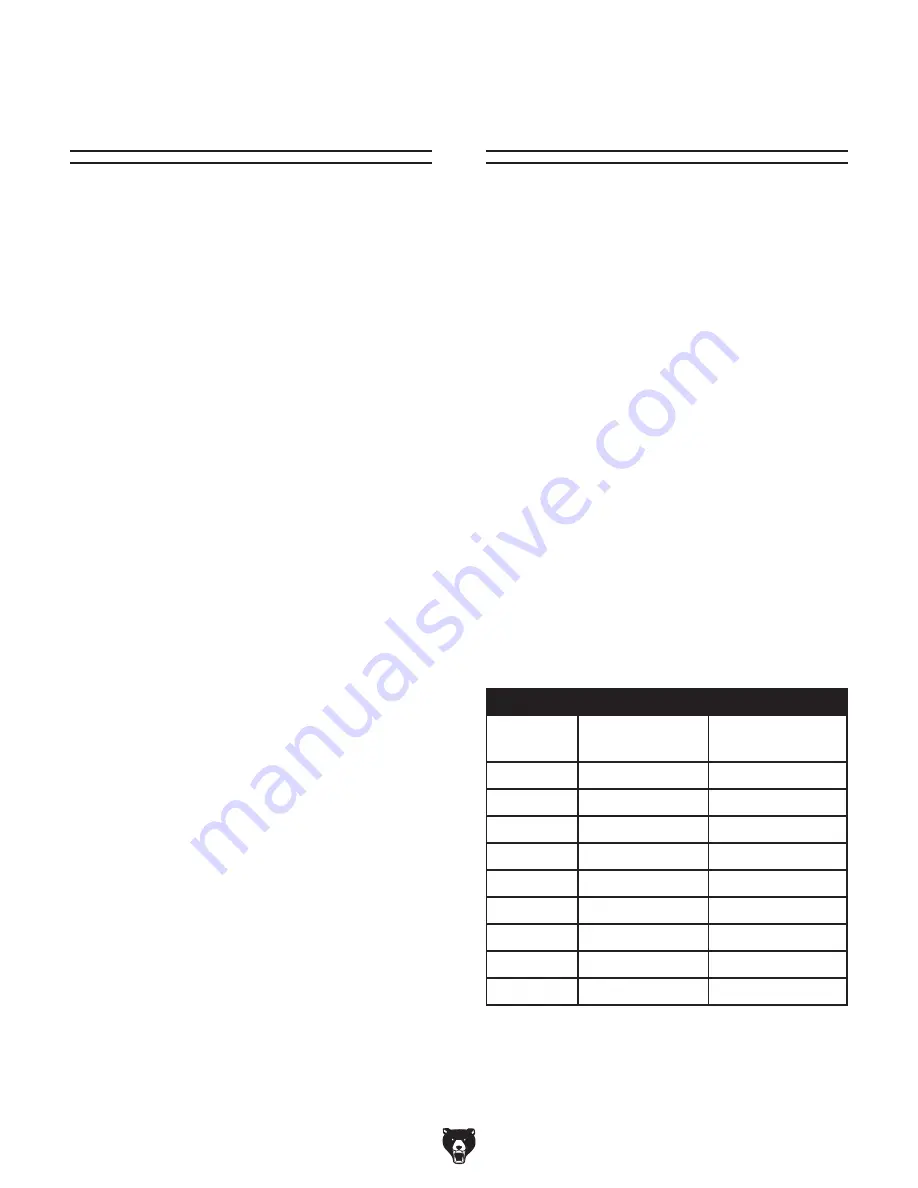

Material Cutting Power/Speed Chart

Material

Type

G0911/G0913

Power/Speed

G0912/G0914

Power/Speed

Hardwood

70% - 15mm/s

65% - 20mm/s

Softwood

55% - 25mm/s

40% - 30mm/s

MDF

75% - 15mm/s

65% - 20mm/s

Acrylic

75% - 15mm/s

65% - 20mm/s

PVC

60% - 50mm/s

50% - 60mm/s

Rubber

75% - 15mm/s

70% - 20mm/s

Leather

75% - 15mm/s

70% - 20mm/s

Cloth

20% - 150mm/s 20% - 200mm/s

Paper

20% - 150mm/s 20% - 200mm/s

Figure 48. Material cutting power and speed

settings.

-40-

Model G0911–G0914 (Mfd. Since 05/21)

Some materials are not safe for laser cut-

ting, or may be outside the capabilities of your

machine.

Before cutting/engraving, inspect all

workpieces for the following:

•

Engraving Material: This machine is capa-

ble of engraving natural wood, MDF, glass,

acrylic, PVC, rubber, ceramic, leather, cloth,

and paper. This machine is NOT designed to

engrave metal; engraving this material with

this machine may lead to machine damage

or personal injury.

•

Cutting Material: This machine is capable of

cutting natural wood, MDF, acrylic, PVC, rub-

ber, leather, cloth, and paper. This machine

is NOT designed to cut metal, glass, or

ceramics; cutting these materials with this

machine may lead to machine damage or

personal injury.

•

Foreign Objects: Nails, staples, dirt, rocks,

and other foreign objects are often embed-

ded in wood. Always visually inspect your

workpiece for these items. If they cannot be

removed, DO NOT use the workpiece.

•

Wood Knots: Knots in wood are denser

than the natural grain surrounding them, and

may cause unpredictable cutting/engraving

results. Always use wood workpieces that do

not have knots, or position working envelope

away from visibly knotted areas to maintain

consistent cutting/engraving quality.

•

Wet or "Green" Wood: Avoid using wood

with a high water content. Wood exposed to

excessive moisture (such as rain or snow), will

cut/engrave poorly and cause large clouds of

smoke and debris inside the machine.

•

Excessive Warping: Workpieces with exces-

sive cupping, bowing, or twisting are diffi-

cult to cut/engrave due to inconsistent sur-

face height negatively affecting focal length.

Always use flat stock to maintain consistent

cutting/engraving depth.

•

When cutting/engraving acrylic, use a raised,

nonreflective surface that promotes airflow

underneath the workpiece. This will help

prevent refracted laser rays from melting the

surface and causing blemishes.

•

Plywoods are formed from bonding many dif-

ferent wood types together using adhesive.

The adhesive used to bond the plies will

regularly ignite during cutting/engraving and

cause unwanted surface defects. Use solid

wood for optimal finish quality.

•

Use the

Material Cutting Power/Speed

Chart below as a guide for determining opti-

mal power/speed settings for cutting

1

⁄

4

" thick

wood or plastic with your machine. Always

test new settings on scrap material first, then

make adjustments as necessary until desired

cutting results are achieved.

Note: Engraving settings require too many

variables to effectively list here. A good start-

ing point for most hardwoods is 30% power

and 300mm/s speed.

Inspecting

Workpiece

Cutting/Engraving

Tips

Summary of Contents for G0911

Page 100: ......