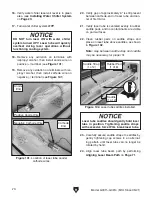

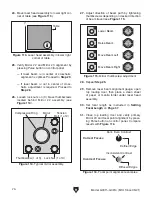

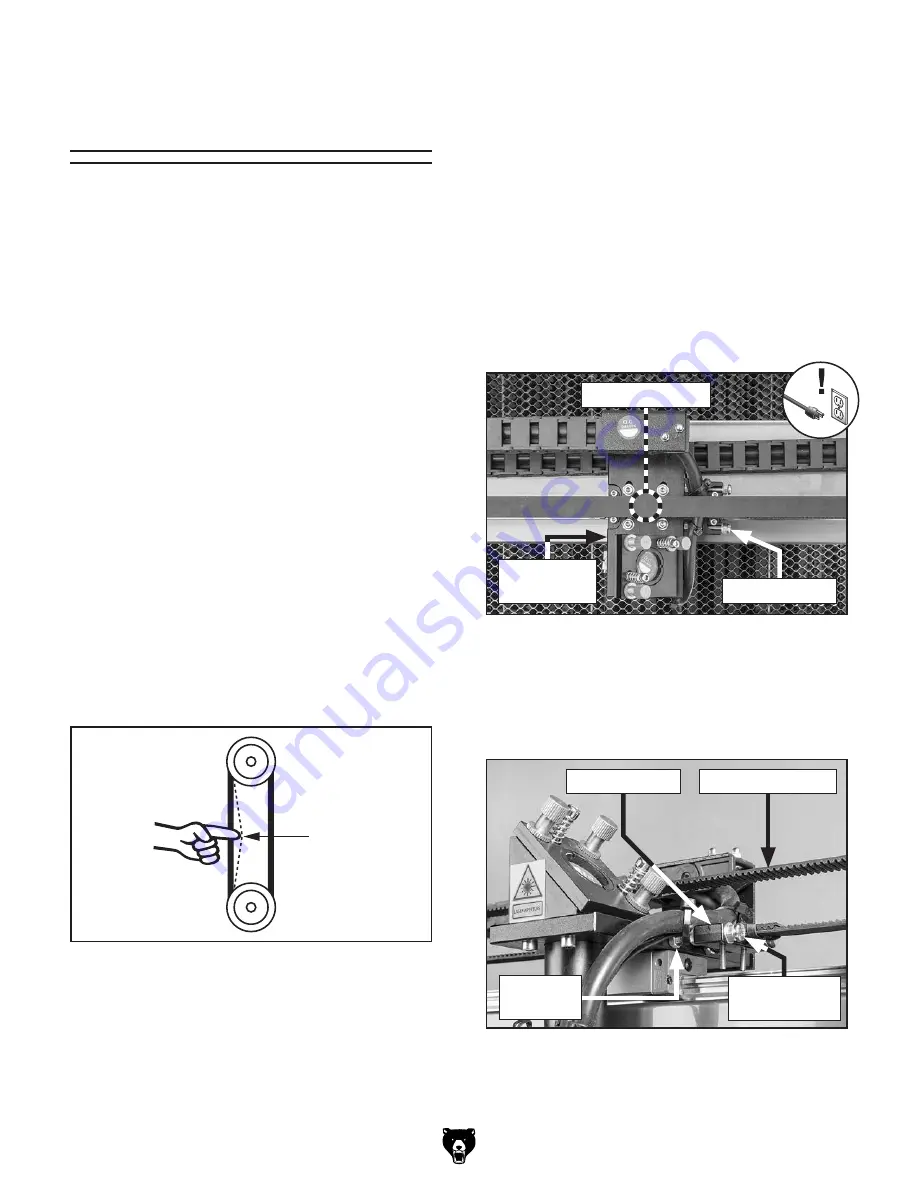

Figure 75. X-axis belt tensioner components.

Pulley

Pulley

Deflection

Figure 73. Testing belt deflection.

Figure 74. X-axis belt deflection testing location.

Model G0911–G0914 (Mfd. Since 05/21)

-59-

The Model G0911–G0914 uses toothed synchro-

nous belts that engage with a cogged drive pulley.

After long-term use, one or more synchronous

belts may have to be adjusted. To maximize belt

life, and maintain adequate cut quality, follow

these recommended guidelines:

•

Unlike V-belts, the synchronous belts must

not be allowed to slip under any circum-

stances, or the workpiece will be ruined

due to laser coordinates straying from the

programmed path. Synchronous belt tension

only needs to keep the belt teeth engaged

with the pulley cogs under a light load.

•

Excessive belt tension will wear out delicate

pulley bearings and stretch the belt.

•

Insufficient belt tension will cause noisy direc-

tional changes due to belt slip, and reduce

resolution quality of the cut.

The following sections show proper belt tension

deflection values for each axis. See

Figure 73 for

a typical method of testing belt deflection using

moderate pressure.

Adjusting

Synchronous Belts

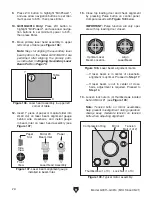

X-Axis Belt Adjustment

1. DISCONNECT MACHINE FROM POWER!

2. Open top loading door and center laser head

assembly over table.

3. Test for approximately 10mm of deflection on

top side of belt at its center (see

Figure 74).

— If belt deflection is approximately 10mm,

no adjustment is required.

— If belt deflection is greater than or less

than 10mm, proceed to

Step 4.

Items Needed

Qty

Caliper or Precision Ruler ................................. 1

Hex Wrenches 2.5, 3mm .............................1 Ea.

Open-End Wrench 7mm .................................... 1

Phillips Head Screwdriver #2 ............................ 1

Clean Shop Rags .............................. As Needed

4. To adjust belt tension, loosen (4) jam nuts on

belt tensioner, loosen or tighten (2) Phillips

head screws, then secure jam nuts (see

Figure 75). Repeat Step 3.

Belt Tensioner

Testing Location

Laser Head

Assembly

Synchronous Belt

Phillips Head

Screw (1 of 2)

Jam Nut

(1 of 4)

Belt Tensioner

Summary of Contents for G0911

Page 100: ......