Only remove one leadscrew at a time to

maintain adequate table support or machine

damage and personal injury may occur!

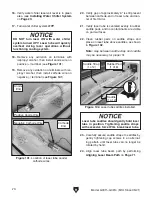

Figure 87. Z-axis table support brackets

location.

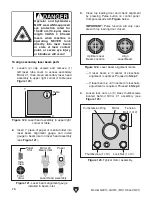

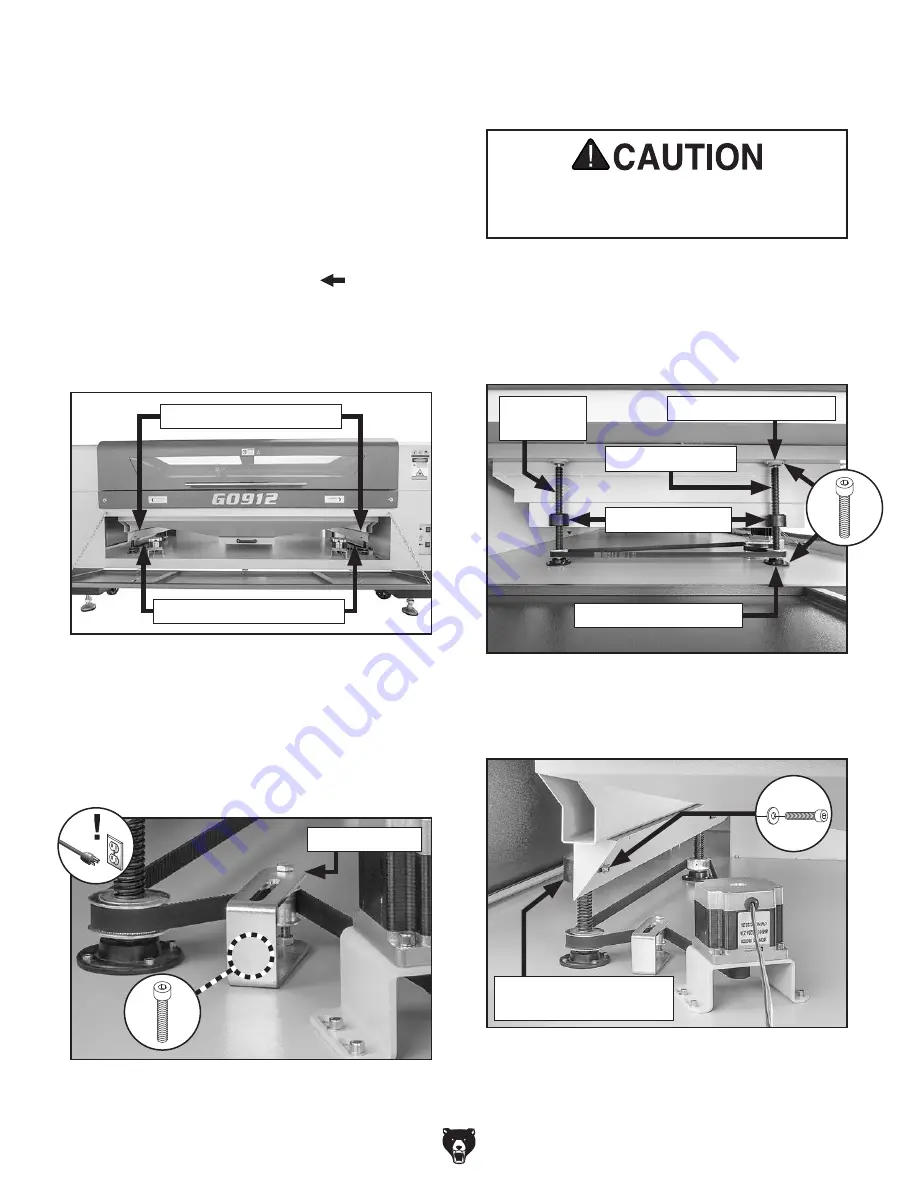

Figure 90. Leadscrew nut cap screw location.

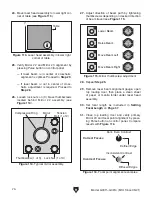

Figure 89. Leadscrew components location.

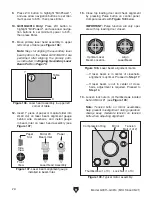

Figure 88. Z-axis belt tensioner components.

x 1

x 6

-64-

Model G0911–G0914 (Mfd. Since 05/21)

Z-Axis Belt Replacement

1. Open front access door.

Note: Z-axis synchronous belt components

are the same on left and right sides.

2. Turn machine ON, press Z/U button on con-

trol panel to access Z/U menu, then highlight

"Z move".

3. Press left arrow nav button (

) on control

panel to raise table enough to fit wood blocks

under both table support brackets between

leadscrews (see

Figure 87). Lower table until

support brackets rest on wood blocks.

4. DISCONNECT MACHINE FROM POWER!

5. Loosen (2) cap screws on belt tensioner, then

pull belt tensioner away from belt to release

tension (see

Figure 88).

6. With belt tension released, cut defective belt

and remove from machine.

7. Remove (4) cap screws on front leadscrew

lower mounting base (see

Figure 89).

8. Remove (2) cap screws on front leadscrew

upper mounting base (see

Figure 89).

9. Remove (1) cap screw and flat washer from

front leadscrew nut (see

Figure 90).

Rear

Leadscrew

Upper Mounting Base

Lower Mounting Base

Leadscrew Nuts

Front Leadscrew

Leadscrew Nut

(Behind Table Support)

Table Support Brackets

Place Wood Blocks Here

x 2

Belt Tensioner

Summary of Contents for G0911

Page 100: ......