To avoid damaging laser tube, remove tube

from container ONLY when ready to place

in machine. Handle tube carefully in a pre-

planned manner to prevent tube contacting

machine cabinet.

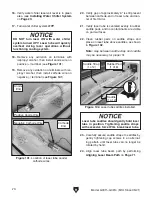

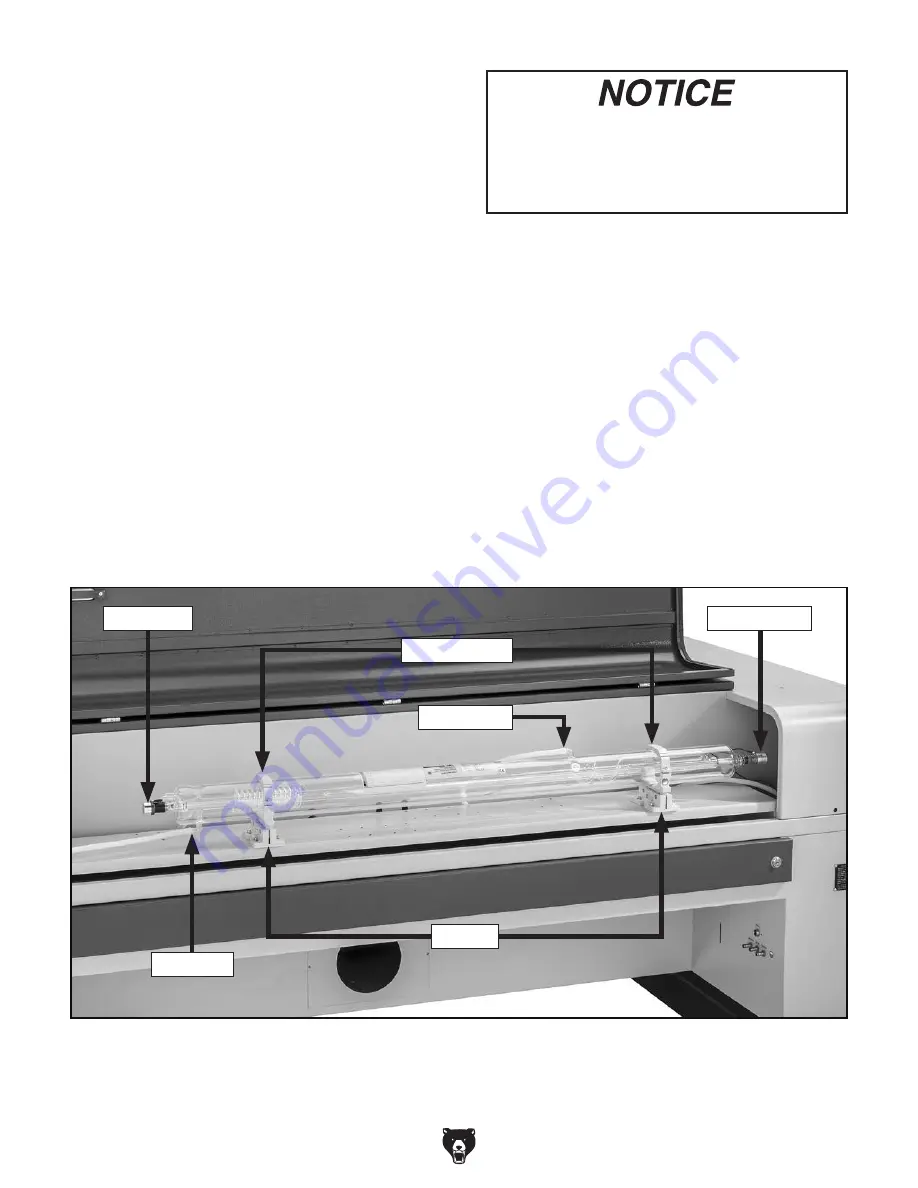

Figure 98. Laser tube compartment identification.

-68-

Model G0911–G0914 (Mfd. Since 05/21)

Installing Laser Tube

1. Inspect laser tube saddles and rubber pads

for any debris or foreign material, and clean

as required (see

Figure 98).

IMPORTANT: When inspecting and setting

up machine for laser tube installation, DO

NOT loosen or reposition laser tube sad-

dles. Saddles are factory-aligned and require

many additional steps to re-align if original

alignment is altered.

2. Carefully open laser tube shipping container.

Note: DO NOT destroy or discard laser tube

shipping container. Retain original box for

ordering replacement tubes, or in the event

of damage caused during shipping.

3. Remove dust caps or tape (if installed) from

laser tube.

IMPORTANT:

DO NOT force caps off water

spout if they cannot be removed by hand.

Carefully cut them off using utility knife.

4. Carefully remove laser tube from shipping

container, and position anode-end on anode

side of tube compartment (see

Figure 98).

5. Gently place laser tube in saddles.

6. Position cathode-end of laser tube so there is

a gap of approximately 6" between end and

center of first mirror (see

Figure 98).

Note: Laser tube has labels showing sug-

gested support location for saddles.

7. Verify inlet and outlet hoses will not interfere

with closed doors or covers, and hoses are

free of kinks that could potentially restrict

water flow to laser tube.

Outlet Hose

Anode End

Cathode End

Saddles

Saddle Straps

Inlet Hose

Summary of Contents for G0911

Page 100: ......