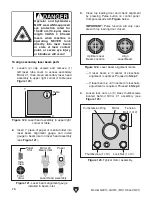

Operator and bystanders

MUST wear ANSI-approved

eye protection rated for

10,600 nm (10.6 µm) wave-

length CLASS 4 infrared

lasers when machine is

operating. NEVER look

directly into laser beam

or stare at laser contact

point, or severe eye injury

or blindness will occur!

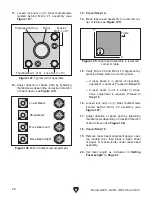

Laser Head Assembly

Front

View

Side

View

Paper

Slot

Mirror #3

Beam Inlet

Paper

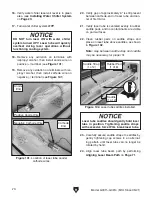

Figure 121. Laser beam alignment gauge

installed in beam inlet.

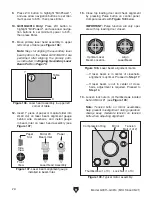

Optimal Laser

Beam Location

Align

Laser Beam

Figure 122. Laser beam alignment marks.

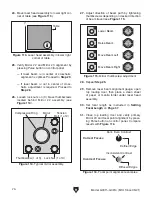

Mirror

Tension

Bolt (1 of 2)

Compression Ring

Thumbscrew (1 of 3)

Lock Nut (1 of 3)

Figure 123. Typical mirror assembly.

X

Y

Table

Figure 120. Laser head assembly in upper right

corner of table.

-76-

Model G0911–G0914 (Mfd. Since 05/21)

3.

Close top loading door and check alignment

by pressing Pulse button on control panel.

Compare results with

Figure below.

IMPORTANT: Pulse function will only oper-

ate with top loading door closed.

— If laser beam is in center of crosshairs,

alignment is optimal. Proceed to

Step 7.

— If laser beam is not in center of crosshairs,

adjustment is required. Proceed to

Step 4.

4.

L

oosen lock nuts on (3) brass thumbscrews

located behind Mirror #1 assembly (see

Figure 123).

2.

Insert 1" piece of paper or manila folder into

laser beam alignment gauge, and install

gauge in beam inlet on laser head assembly

(see

Figure 121).

To align secondary laser beam path:

1. Loosen (4) cap screws and remove (1)

left laser tube cover to access secondary

Mirror #1, then m

ove secondary laser head

assembly to upper right corner of table (see

Figure 120).

Summary of Contents for G0911

Page 100: ......