EYE INJURIES. Operator and bystanders MUST

wear ANSI-approved eye protection rated for use

with a Class 4 laser when machine is operating.

DO NOT look directly into laser beam, or stare at

laser contact point for more than a few seconds,

or severe eye injury or blindness may result.

AVOID SKIN BURNS. NEVER put hands in or

near path of laser. Material cut by a laser can be

hot. ALWAYS wear leather gloves when handling

processed material. Allow machine to cool before

starting any adjustment or service/maintenance

procedure.

FIRE HAZARD. Laser beam produces extremely

high temperatures and significant amounts of heat

as material is cut. DO NOT process materials that

are highly flammable or explosive. Keep flamma-

ble materials well away from machine during oper-

ations. If materials do catch fire during operations,

extinguish immediately. ALWAYS keep a properly

maintained fire extinguisher nearby.

REFLECTIVE MATERIALS. DO NOT process

materials with reflective surfaces. These materials

will redirect the laser beam, exposing operator

and bystanders to serious injury, and causing

damage to mechanical and electrical components

inside machine.

Severe eye injury or blindness can occur from looking directly into laser beam, or staring at

laser contact point for more than a few seconds. Touching hot machine parts and workpieces

can cause serious skin burns. To reduce these risks, operator and bystanders MUST complete-

ly heed the warnings below.

UNATTENDED MACHINE. DO NOT leave

machine unattended during operation. Materials

may catch fire during operation. Fires MUST be

extinguished immediately to prevent personal

injury or property damage.

SAFETY DEVICES. DO NOT modify or disable

safety devices on machine. Laser is designed

to shut off if cover is opened. Severe injury may

occur if operator or bystanders come into contact

with laser beam during operation.

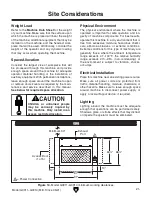

SAFE OPERATING LOCATION. DO NOT place

machine where it can be exposed to rain or mois-

ture. Exposure to water creates a shock hazard

and will reduce life of machine.

POWER DISCONNECT. To reduce risk of elec-

trocution or injury from unexpected startup, make

sure machine is turned OFF and disconnected

from power before starting any inspection, adjust-

ment, or service/maintenance procedure.

PROPERLY MAINTAIN MACHINE. Keep

machine in proper working condition to help

ensure all safety components function as intend-

ed. Perform routine inspections and all necessary

maintenance indicated in owner’s manual. Never

operate machine with damaged or worn parts.

No list of safety guidelines can be complete.

Every shop environment is different. Always

consider safety first, as it applies to your

individual working conditions. Use this and

other machinery with caution and respect.

Failure to do so could result in serious per-

sonal injury, damage to equipment, or poor

work results.

No list of safety guidelines can be complete.

Every shop environment is different. Always

consider safety first, as it applies to your

individual working conditions. Use this and

other machinery with caution and respect.

Failure to do so could result in serious per-

sonal injury, damage to equipment, or poor

work results.

Like all machinery there is potential danger

when operating this machine. Accidents are

frequently caused by lack of familiarity or

failure to pay attention. Use this machine

with respect and caution to decrease the

risk of operator injury. If normal safety pre-

cautions are overlooked or ignored, serious

personal injury may occur.

-14-

Model G0911–G0914 (Mfd. Since 05/21)

Additional Safety for

CNC Laser Cutters/Engravers

Summary of Contents for G0911

Page 100: ......