-38-

Model G0920 (Mfd. Since 10/20)

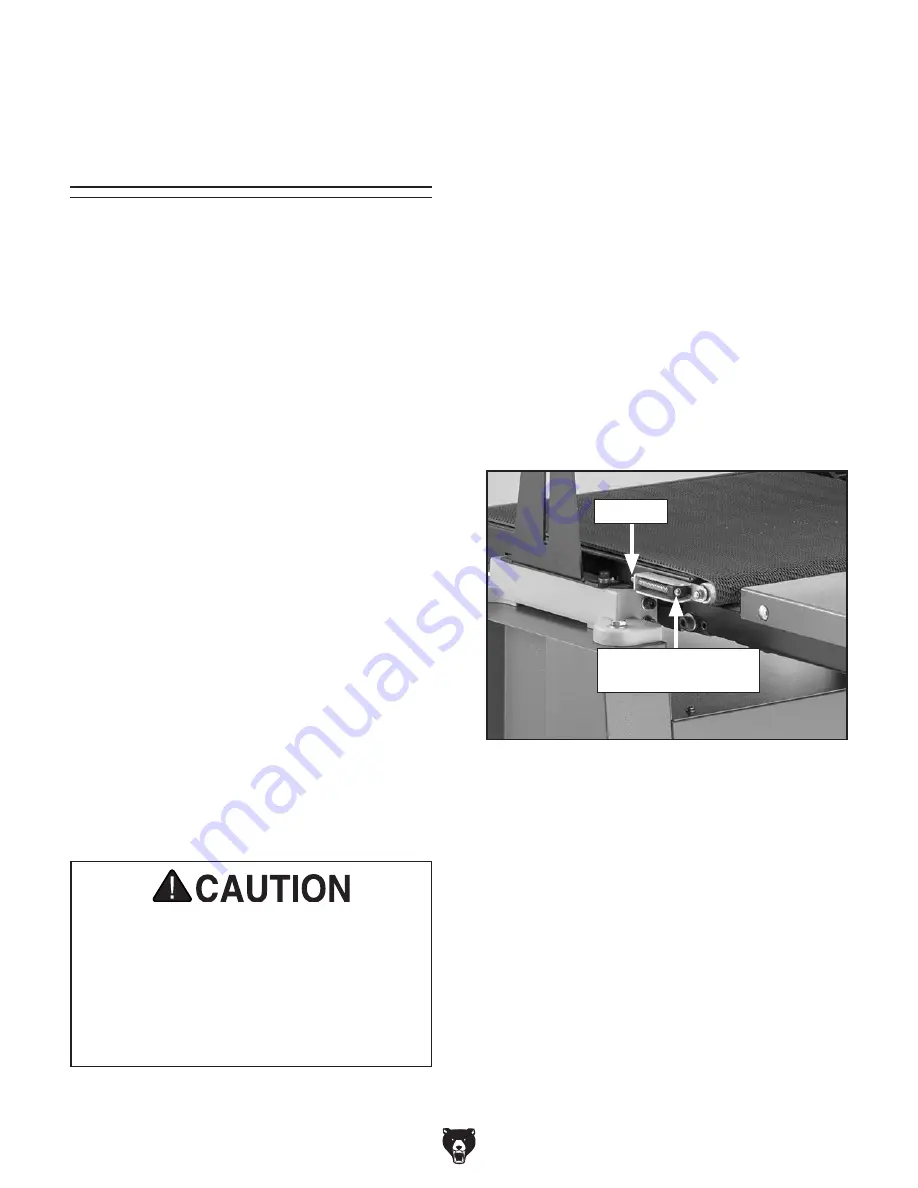

2. Hold lock nut still on side that conveyor belt

tracks towards and tension tracking adjust-

ment screw until conveyor belt tracks in

opposite direction (see

Figure 52).

Note: Small tracking changes may take up to

three minutes before they are noticeable.

3. When conveyor belt is near middle of rollers

or table, loosen tracking adjustment screw

while holding lock nut still until feed belt stops

moving and tracks straight.

Figure 52. Conveyor belt tracking adjustment

screw and lock nut.

Lock Nut

Tracking Adjustment

Screw

— If belt tracks evenly, no adjustment is

required.

Working around moving conveyor and parts

presents pinch/entanglement hazards that

can cause personal injury. Use extreme

care to keep hands clear of in-running pinch

points while adjusting tracking nut/screw

when machine is running. Roll up sleeves

and do not wear gloves or other apparel that

could become entangled in moving parts.

1. Turn machine ON and watch conveyor belt

track.

— If belt quickly moves to one side, immedi-

ately stop machine and adjust belt tracking

before running conveyor again. Proceed

to

Step 2.

Tracking Conveyor Belt

— If conveyor belt tracks too far to other side,

hold lock still and loosen tracking adjust-

ment screw as necessary to bring it back.

Repeat

Steps 2–3 until tracking is correct.

4. Tracking affects tension, so refer to

Tensioning Conveyor Belt on next page.

Tracking &

Tensioning

Conveyor Belt

The conveyor belt must track straight. If the feed

belt tracks to either side, then the tracking must

be corrected or the conveyor belt will become

damaged and have to be replaced. The track-

ing was properly set at the factory, but wear may

cause it to track unevenly eventually.

Tracking the conveyor belt is a balancing process

that takes patience and some trial-and-error.

Usually you must over-tighten the loose side to

make the belt move to the middle of the rollers,

then loosen that same side to make the feed

belt stay in position. If the tracking screw is over-

adjusted, then the process will need to be repeat-

ed until the conveyor belt stays in the middle.

The conveyor belt will stretch when new and will

eventually need to be tensioned. This is most

obvious if the conveyor belt starts slipping on the

rollers.

When you tension the conveyor belt, focus on

adjusting the tensioning bolts in even increments.

Adjusting one side more than the other will cause

tracking problems, which will require you to make

additional adjustments to get the sander tracking

correctly again.

Items Needed

Qty

Open-End Wrench 10mm .................................. 1

Phillips Head Screwdriver #2 ............................ 1

Calipers ............................................................. 1

Summary of Contents for G0920

Page 60: ......