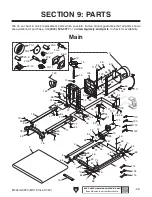

Model G0920 (Mfd. Since 10/20)

-41-

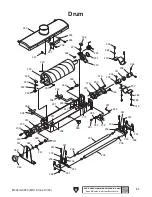

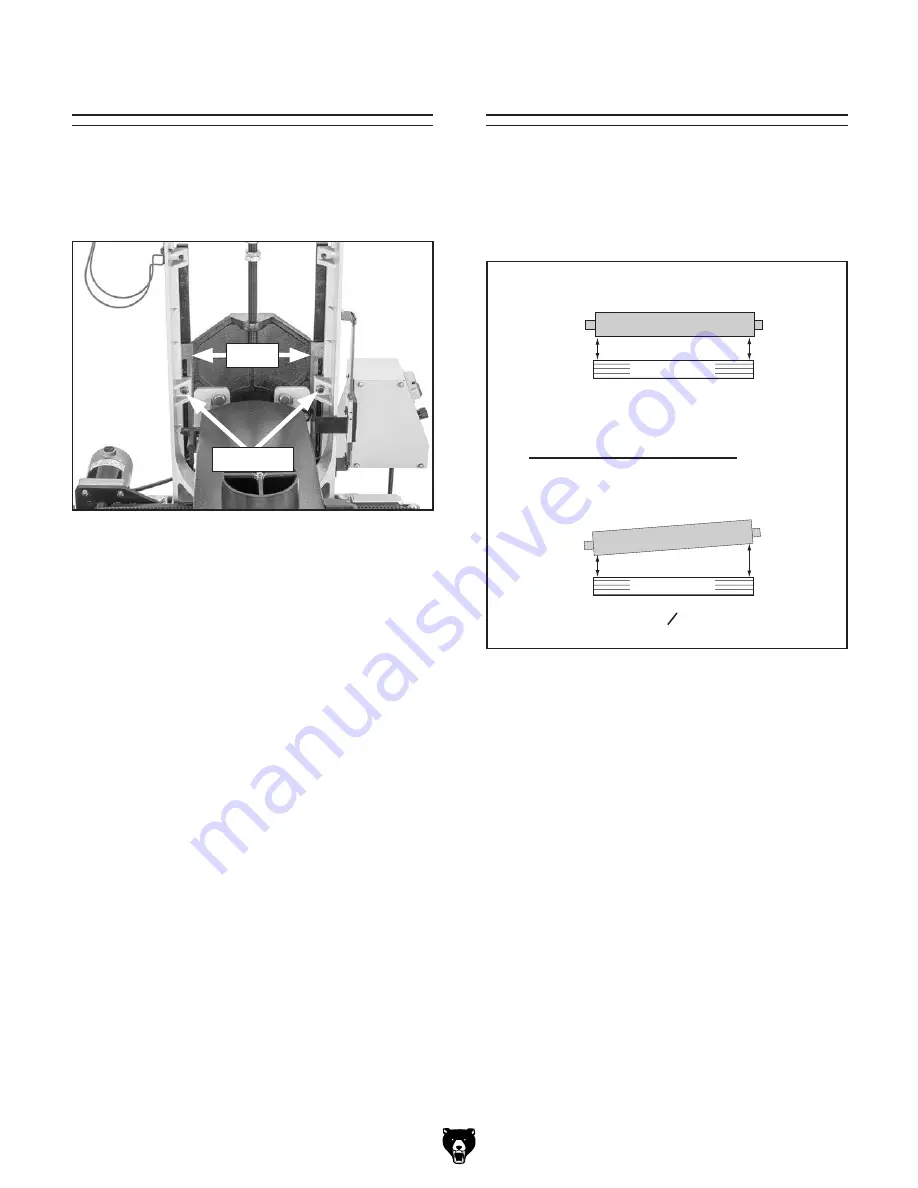

The gibs apply pressure to the slides of the sand-

ing head (see

Figure 58). This allows the sanding

head assembly to accurately move up and down

when using the drum height handwheel.

Figure 58. Location of rear slide and lock nut.

If the gibs are too loose, the sanding drum will

deflect up during operation, which will result in

poor sanding results.

If the gibs are too tight, it will be difficult to adjust

the sanding drum height, which will cause exces-

sive wear on the parts of the elevation system.

Adjusting Gibs

Tools Needed

Qty

Socket 13mm ..................................................... 1

Hex Wrench 6mm .............................................. 1

To adjust gibs:

1. DISCONNECT MACHINE FROM POWER!

2. Adjust lock nuts shown in Figure 58 on both

gibs an equal amount, by

1

/

4

turns.

3. Rotate drum height handwheel to test drum

movement.

Note: Tighten lock nuts to increase gib

pressure.

4. Repeat Step 2–3 until you are satisfied with

drum movement.

Slides

Lock Nuts

Aligning Drum

Aligning the drum parallel to the conveyor belt

(see

Figure 59) is critical for sanding accuracy.

Care should be taken to make the tolerances as

close as possible (within 0.010" from one side to

the other) when adjusting the drum height.

(Front View)

CORRECT

INCORRECT

B

A

B

A

B

=

A

=

A

B

(Within 0.010" side-to-side)

Sanding Drum

Sanding Drum

Conveyor Belt

Conveyor Belt

Figure 59. Drum parallel to conveyor belt.

Tools Needed:

Qty

Wrench or Socket 13mm, 17mm ....................... 1

Hex Wrench 6mm .............................................. 1

Gauge Blocks .................................................... 2

Feeler Gauge Set .............................................. 1

To align sanding drum:

1. DISCONNECT MACHINE FROM POWER!

2. Make sure gibs are properly adjusted (refer to

Adjusting Gibs).

Aligning Drum

Summary of Contents for G0920

Page 60: ......