-42-

Model G0920 (Mfd. Since 10/20)

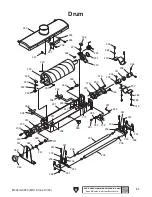

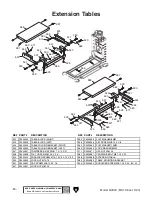

3. Remove sandpaper from drum and place

gauge blocks as shown in

Figure 60.

4. Lower drum until gauge blocks just touch

drum.

5. Raise drum one full crank of handwheel.

6. Starting at A board (see Figure 60), find larg-

est size feeler gauge that can pass between

drum and your gauge block. (Feeler gauge

should slide with moderate resistance, with-

out forcing drum to roll.)

7. Repeat Step 6 at B board.

— If difference between A and B is 0.010" or

less, then no adjustment is necessary.

— If difference between A and B is more than

0.010", then one end must be adjusted to

within 0.010" of other. Proceed to

Step 8.

Figure 60. Example of gauge blocks placed

under drum.

A

B

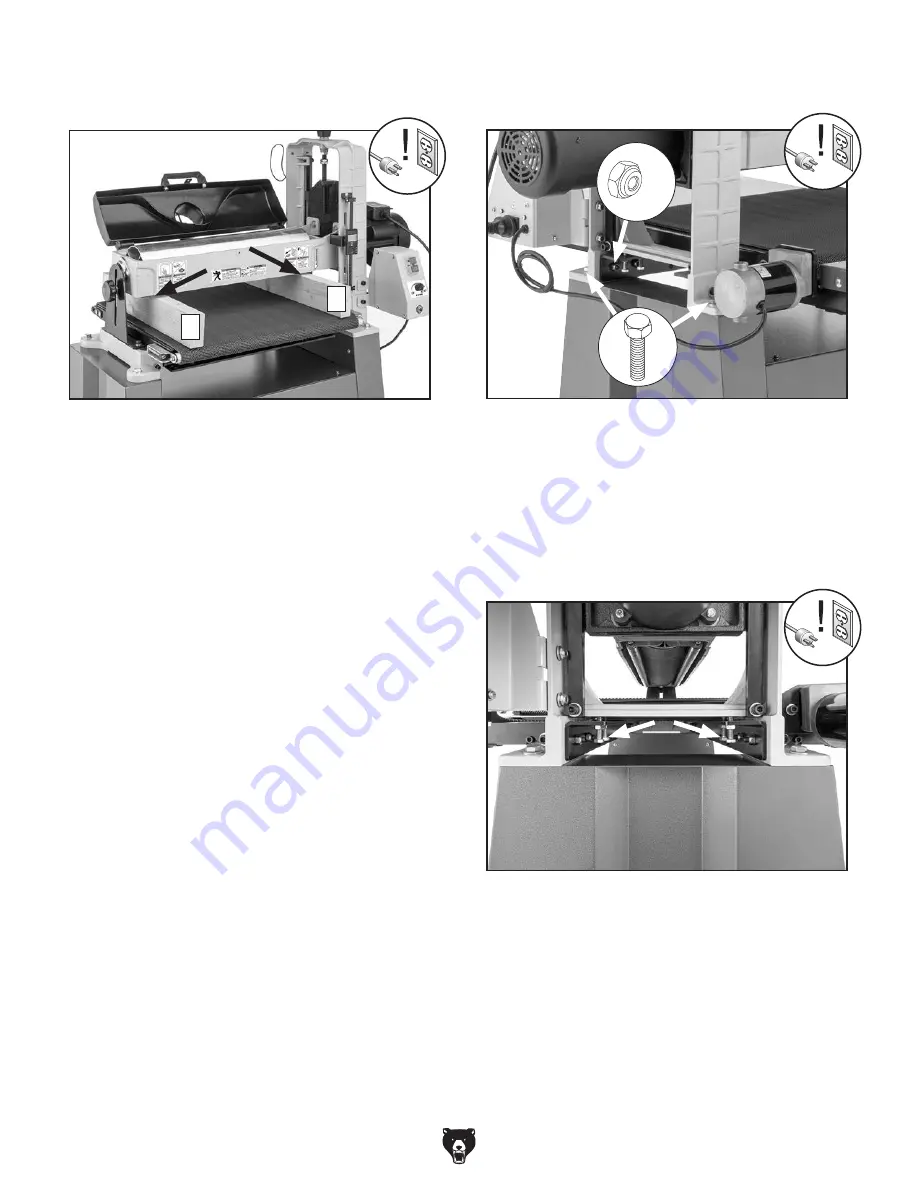

8. Loosen (4) lock nuts and (2) hex bolts shown

in

Figure 61.

9. Refer to measurements taken in Steps 6–7.

— If A measurement was larger than B mea-

surement, loosen (2) hex nuts shown in

Figure 62 and tighten (2) hex bolts until

measurements are equal.

Figure 62. Adjustment hardware for right side.

Figure 61. Mounting hardware to loosen for

drum adjustment.

x 4

Summary of Contents for G0920

Page 60: ......