-18-

Model G0926 (Mfd. Since 11/20)

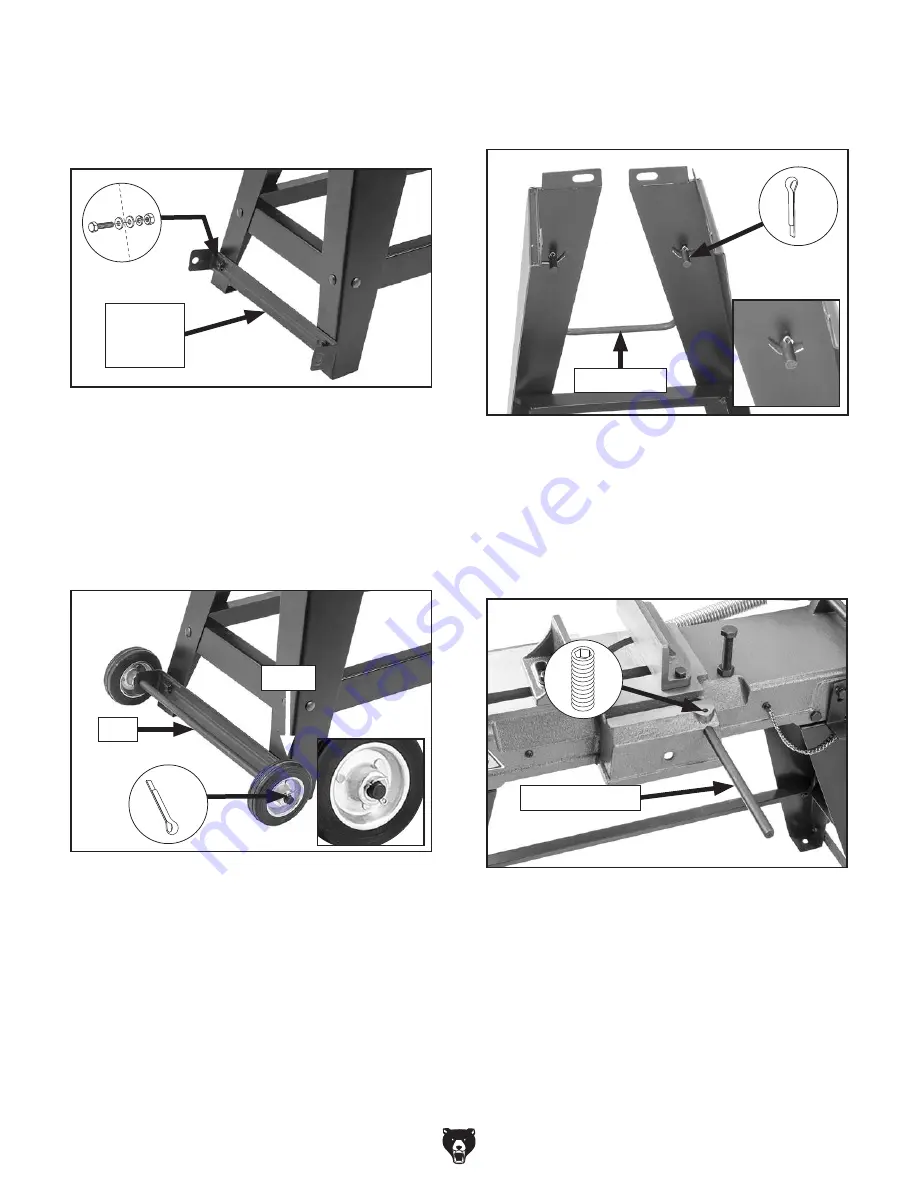

6. Attach wheel mounting bracket to bottom of

two legs with (2) M6-1 x 12 hex bolts, (4) 6mm

flat washers, (2) 6mm lock washers, and (2)

M6-1 hex nuts, as shown in

Figure 13.

Figure 13. Wheel-mounting bracket attached to

legs.

Wheel

Mounting

Bracket

Figure 14. Wheels attached to axle.

Figure 15. Cotter pins installed in handle.

7. Slide wheel axle through holes in wheel-

mounting bracket (see

Figure 14).

8. Slide wheels onto axle on outside of mount-

ing brackets, and secure with (2) cotter pins

(see

Figure 14).

9. On opposite side of stand, insert pull handle

into holes shown in

Figure 15 and secure

with (2) cotter pins.

10. Check to see if bandsaw is relatively level,

then fully tighten all bolts and nuts.

11. Slide work stop rod into side of bandsaw,

then lock it in place by tightening set screw

shown in

Figure 16.

x 2

x 2

Wheel

Axle

Pull Handle

x 2

Figure 16. Work stop rod installed.

Work Stop Rod

Summary of Contents for G0926

Page 56: ......