Model G0945/G0946/G0947 (Mfd. Since 06/21)

-35-

Operation

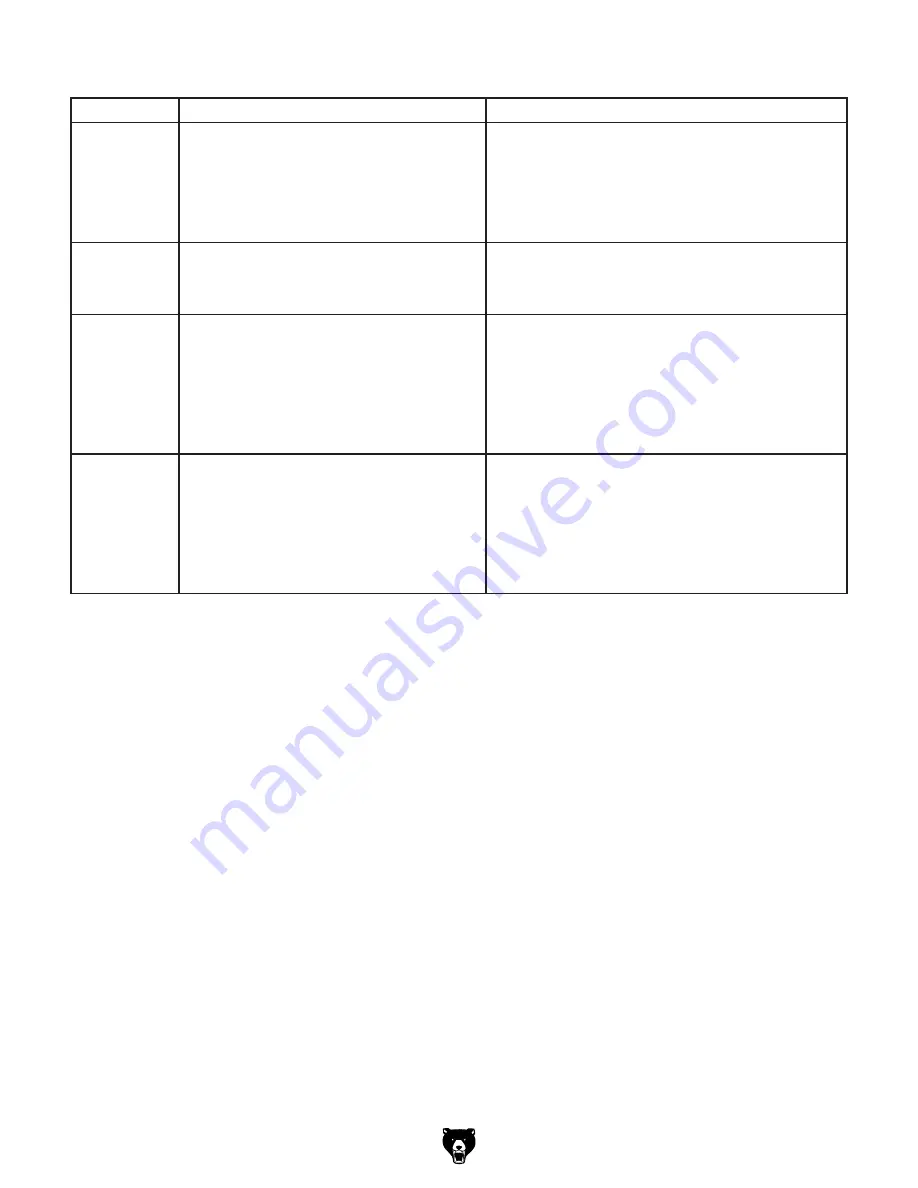

Symptom

Possible Cause

Possible Solution

Uneven cutter

marks, wavy

surface, or

chatter marks

across face of

workpiece.

1. Feeding workpiece too fast.

2. Knives/insert(s) not adjusted at even heights

in cutterhead.

3. Dirt or debris under carbide insert(s) (G0946/

G0947 only).

1. Reduce feed rate.

2. Adjust knives so they are set up evenly in cutterhead

(

Page 38). Remove, clean, and re-install any inserts

that are "raised" in cutterhead (

Page 36).

3. Remove insert(s), clean bottom of insert/cutterhead

mounting pocket, and re-install (

Page 36).

Glossy surface;

scorching or

burn marks on

workpiece.

1. Dull knives/insert(s).

2. Feed rate too slow.

1. Sharpen/replace knives (Page 38); rotate/replace

insert(s) (

Page 36).

2. Increase feed rate.

Workpiece is

concave or

convex along

its length after

jointing.

1. Workpiece not held with even pressure

against outfeed table during cut.

2. Workpiece too uneven at start of operation.

3. Tables not parallel with cutterhead body and

each other.

4. Table extensions not parallel with tables.

1. Apply even downward pressure against workpiece

throughout entire travel along outfeed side during cut.

2. Take partial cuts to remove extreme high spots before

doing a full pass.

3. Check/adjust table parallelism (Page 39).

4. Check/adjust table extension parallelism (Page 43).

Workpiece

edges not

square; tapered

cut produced.

1. Fence not square to table(s); fence tilt

unlocked.

2. Warped infeed or outfeed table.

3. Knives/insert(s) not adjusted at even heights

in cutterhead.

4. Table extensions not parallel with tables.

1. Square fence to table(s); lock fence.

2. Regrind/replace table.

3. Adjust knives so they are set up evenly in cutterhead

(

Page 38). Remove, clean, and re-install any inserts

that are "raised" in cutterhead (

Page 36).

4. Check/adjust table extension parallelism (Page 43).

Summary of Contents for G0945

Page 60: ......