Model G0948 (Mfd. Since 08/21)

-33-

Using Positive Stop

The positive stop (see

Figure 39) allows you to

quickly return the table to 0° from a right-tilt set-

ting. The positive stop is adjustable, allowing for

calibration, or if desired, minor deviations from 0°.

To use positive stop:

1. DISCONNECT MACHINE FROM POWER!

2. Loosen table tilt lock lever (see Figure 38 on

Page 32).

3. Tilt table to desired angle, then secure posi-

tion by tightening table tilt lock lever (see

Figure 38 on Page 32).

4. Loosen jam nut on stop bolt (see Figure 39),

and turn bolt until it just touches bottom of

table.

5. Tighten jam nut to secure stop bolt setting.

Note: It is always a good idea to check table

tilt scale and make sure positive stop bolt is

correctly calibrated.

To check/calibrate positive stop:

1. DISCONNECT MACHINE FROM POWER!

2. Loosen table tilt lock lever, and tilt table to

approximately 10° right.

3. Loosen positive stop jam nut, and lower posi-

tive stop bolt so it will not interfere with the

following steps.

4. Place a machinist's square flat on table against

side of blade, as illustrated in

Figure 40.

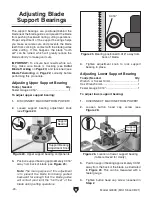

Checking/Calibrating Positive Stop

Tool(s) Needed

Qty

Open-End Wrenches 10, 14mm ..................1 Ea.

Machinist's Square ............................................ 1

Tool(s) Needed

Qty

Open-End Wrenches 10, 14mm ..................1 Ea.

Figure 40. Squaring table to blade.

5. Tilt table until it is square with blade.

6. Adjust positive stop bolt so it just touches

bottom of table, and tighten jam nut to secure

position.

7. Check table to ensure it is square with blade.

If necessary, repeat

Step 5.

Note: If you wish to set the positive stop to an

angle other than 0°, follow

Steps 1–5 for the

desired angle.

8. Loosen screw on table tilt scale indicator,

align pointer with zero on scale, then tighten

screw.

calibrating positive stop

Figure 39. Location of positive stop bolt and jam

nut.

Jam Nut

Positive

Stop Bolt

Summary of Contents for G0948

Page 68: ......