Model G0948 (Mfd. Since 08/21)

-35-

•

Raker: Considered to be the standard

because the tooth size and shape are the

same as the tooth gullet. The teeth on raker

blades usually are very numerous, have no

angle, and produce cuts by scraping the

material. As a result, smooth cuts can be

achieved without cutting fast or generating

more heat than other tooth types.

•

Skip: Similar to a raker blade that is missing

every other tooth. Because of the design,

skip toothed blades have a much larger gullet

than raker blades, and therefore, cut faster

and generate less heat. However, these

blades also leave a rougher cut than raker

blades.

•

Hook: The teeth have a positive angle (down-

ward) which makes them dig into the material,

and the gullets are usually rounded for easier

waste removal. These blades are excellent

for the tough demands of resawing and rip-

ping thick material.

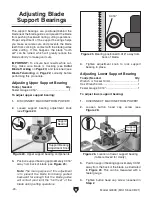

Raker

Skip

Hook

Figure 43. Main blade tooth styles.

Tooth Pitch

Measured as TPI (teeth per inch), tooth pitch

determines the number of teeth. More teeth per

inch (fine pitch) will cut slower, but smoother; while

fewer teeth per inch (coarse pitch) will cut rougher,

but faster. As a general rule, choose blades that

will have at least three teeth in the material at all

times. Use fine-pitched blades on harder woods

and coarse-pitched blades on softer woods.

Tooth Style

Figure 43 illustrates the three main blade tooth

styles:

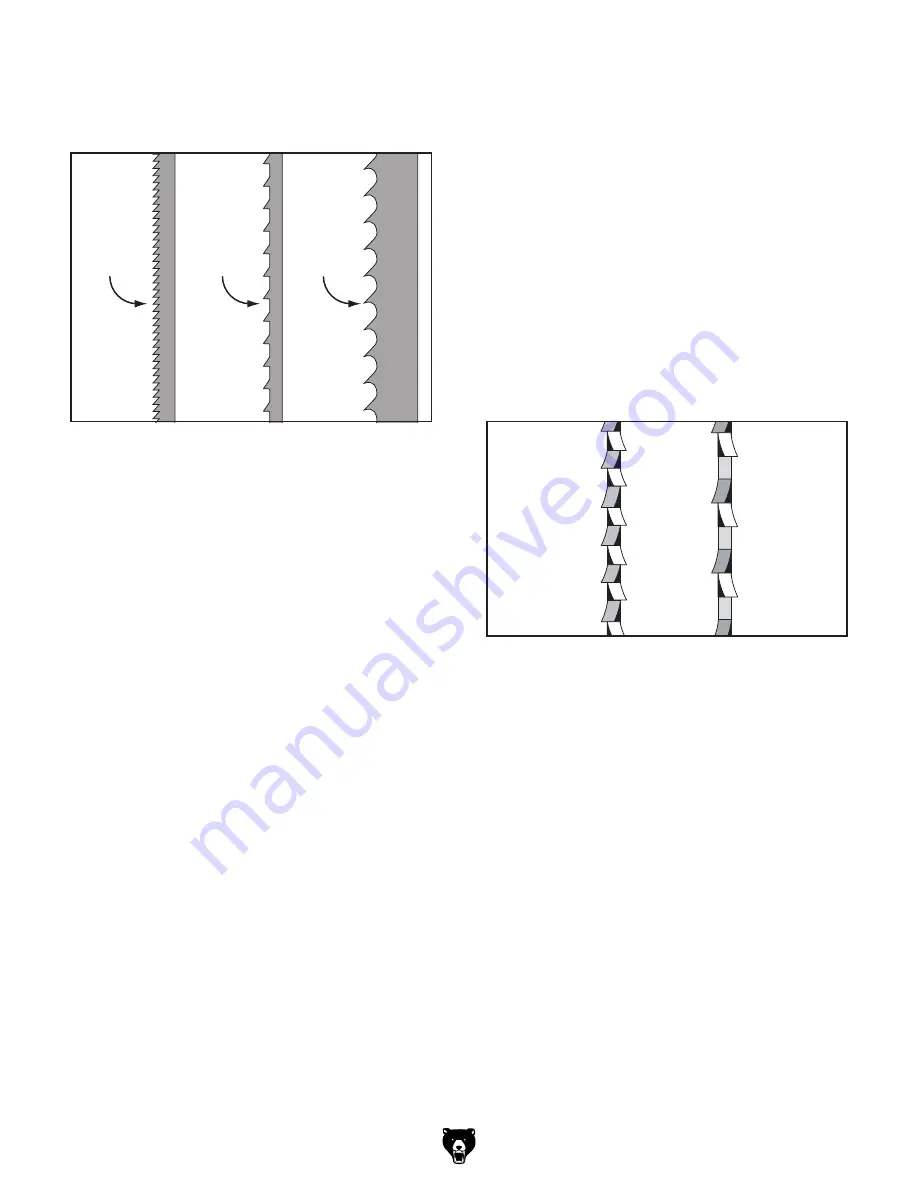

Tooth Set

Two common tooth sets for wood bandsaw blades

are alternate and raker. Each different type of

tooth set removes material in a different manner,

leaving cuts with different characteristics (see

Figure 44).

Alternate

Raker

Figure 44. Common woodcutting bandsaw blade

tooth sets.

•

Alternate: An all-purpose arrangement

where the teeth are bent evenly left and right

of the blade.

•

Raker: Three teeth in a recurring group—one

bent left, one bent right, and then one that is

not bent. The raker set is ideal for most con-

tour cuts.

Summary of Contents for G0948

Page 68: ......