-52-

Model G0948 (Mfd. Since 08/21)

Replacing Belt

Item(s) Needed

Qty

Hex Wrench 6mm .............................................. 1

Retaining Ring Pliers ......................................... 1

Heavy Leather Gloves ..................................1 Pr.

Replacement Belt (Part # P0948105) ................ 1

To replace belt:

1. DISCONNECT MACHINE FROM POWER!

2. Put on heavy leather gloves and remove

blade from machine (refer to

Removing/

Installing Blade on Page 39).

3. Loosen motor mount cap screws (see

Figure 67 on Page 51).

4. Pivot motor to the right (as viewed from back

of bandsaw) to release belt tension.

5. Open lower wheel cover and remove belt

from motor pulley.

To ensure optimum power transmission from the

motor to the blade, the belt must be in good condi-

tion and be properly tensioned.

Replace the belt if it shows signs of cracking, fray-

ing, or excessive wear.

7. Install new belt on both pulleys, and then re-

install wheel and retaining ring.

8. Properly tension belt, as instructed in

Adjusting Belt Tension on Page 51.

9. Install blade, properly track and tension blade

(see

Pages 20 & 22), and adjust support

bearings and guide bearings (see

Pages

24–25).

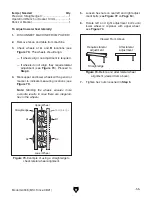

6. Remove external retaining ring from lower

wheel shaft (see

Figure 68) and remove

lower wheel.

Figure 68. Belt change components inside lower

wheel compartment.

External

Retaining Ring

Belt

Summary of Contents for G0948

Page 68: ......