-40-

Model G0948 (Mfd. Since 08/21)

Changing

Blade Speed

Type of Cutting Operation

Blade Speed

(FPM)

General Woodworking

2620

Super Dense Hardwood

1520

Fast/Average Feed Rate

2620

Requires Slow Feed Rate

1520

Rough Edges Acceptable

2620

Requires Smooth Edges

1520

Quick, Production Cuts

2620

Detailed, Intricate Cuts

1520

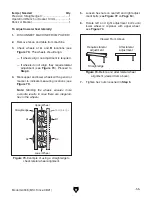

5. Pivot motor clockwise. Apply pressure on

motor so there is approximately

3

⁄

8

" belt

deflection (see

Figure 51), then tighten motor

mount cap screws.

1520 FPM

Motor Pulley

Wheel Pulley

2620 FPM

Figure 50. Belt positions on pulleys.

The Model G0948 offers blade speeds of 1520

and 2620 FPM. Speed changes are made by re-

positioning the V-belt in different pulley grooves.

Keep in mind, cutting results are not just related

to blade speed. Other factors include the type of

workpiece, the blade being used for the operation,

and the feed rate.

Use the chart below as a general guide for which

blade speeds to use for various operations:

Tool(s) Needed

Qty

Hex Wrench 6mm .............................................. 1

1. DISCONNECT MACHINE FROM POWER!

2. Loosen (2) motor mount cap screws (see

Figure 48), and pivot motor counterclockwise

to release belt tension.

3. Open lower wheel cover to reveal motor pul-

ley, wheel pulley, and V-belt (see

Figure 49).

4. Position belt in pulley grooves for desired

speed (see

Figure 50).

Motor Pulley

Approximately

3

/

8

" Deflection

Wheel Pulley

Figure 51. Correct belt deflection.

Figure 48. Location of motor mount cap screws.

Motor Mount

Cap Screws

Figure 49. Location of belt and pulleys.

Wheel

Pulley

Motor

Pulley

Belt

6. Close lower wheel cover.

Summary of Contents for G0948

Page 68: ......