Model G0948 (Mfd. Since 08/21)

-53-

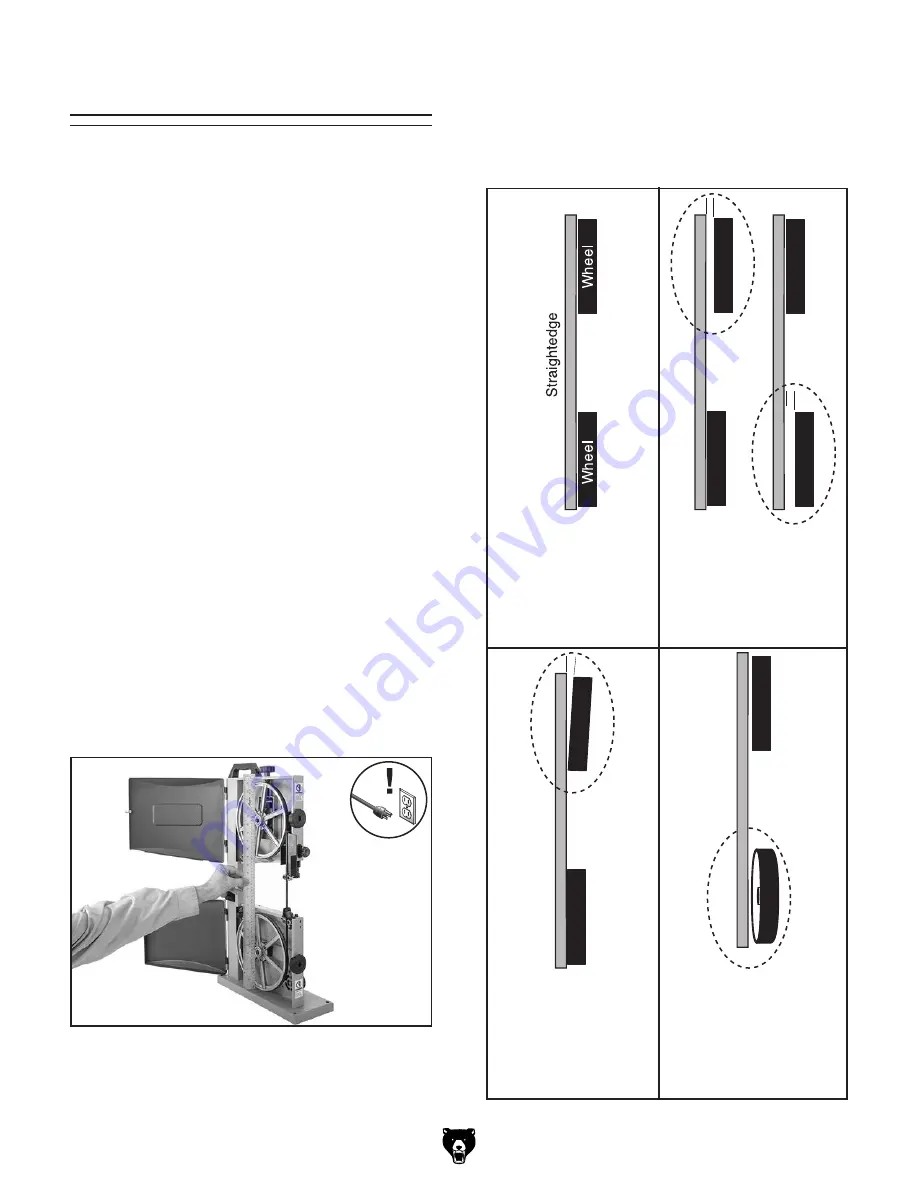

Aligning Wheels

Wheel alignment is important for optimal perfor-

mance from your bandsaw. Wheels are properly

aligned when they are parallel with each other and

in the same plane or “coplanar” (see the illustra-

tion in the figure to the right).

When wheels are coplanar, the bandsaw is

more likely to cut straight without wandering; and

vibration, heat, and blade wear are considerably

decreased because the blade is automatically bal-

anced on the wheel.

Bringing the wheels into alignment may require a

combination of shimming a wheel and adjusting

the position of the lower wheel shaft.

Figure 70. Wheel alignment illustration.

or

Wheels parallel and

aligned: No adjust-

ment needed.

Wheels parallel, but

upper or lower wheel

is not coplanar with the

other wheel: Move the

upper wheel in or out.

Upper wheel is not

vertically aligned with

lower wheel: Use

blade tracking knob

to tilt upper wheel.

Lower wheel is not

laterally aligned with

upper wheel: Adjust

rear adjustment set

bolts to tilt lower wheel

left/right.

4. Check wheel alignment, and adjust tracking

knob to bring both wheels into alignment as

much as possible. If wheels cannot be adjust-

ed coplanar, use

Figure 70 to determine how

to proceed with alignment adjustments.

To check wheel alignment:

1. DISCONNECT MACHINE FROM POWER!

2. Remove table.

3. With blade on and properly tensioned, hold a

straightedge close to center of both wheels.

Make sure straightedge fully extends across

rims of both wheels, as shown in

Figure 69.

Checking Wheel Alignment

Figure 69. Example of checking if wheels are

coplanar.

aligning wheels

Tool(s) Needed

Qty

Precision Straightedge 3'. .................................. 1

Summary of Contents for G0948

Page 68: ......