Model G0949G (Mfd. Since 01/22)

-43-

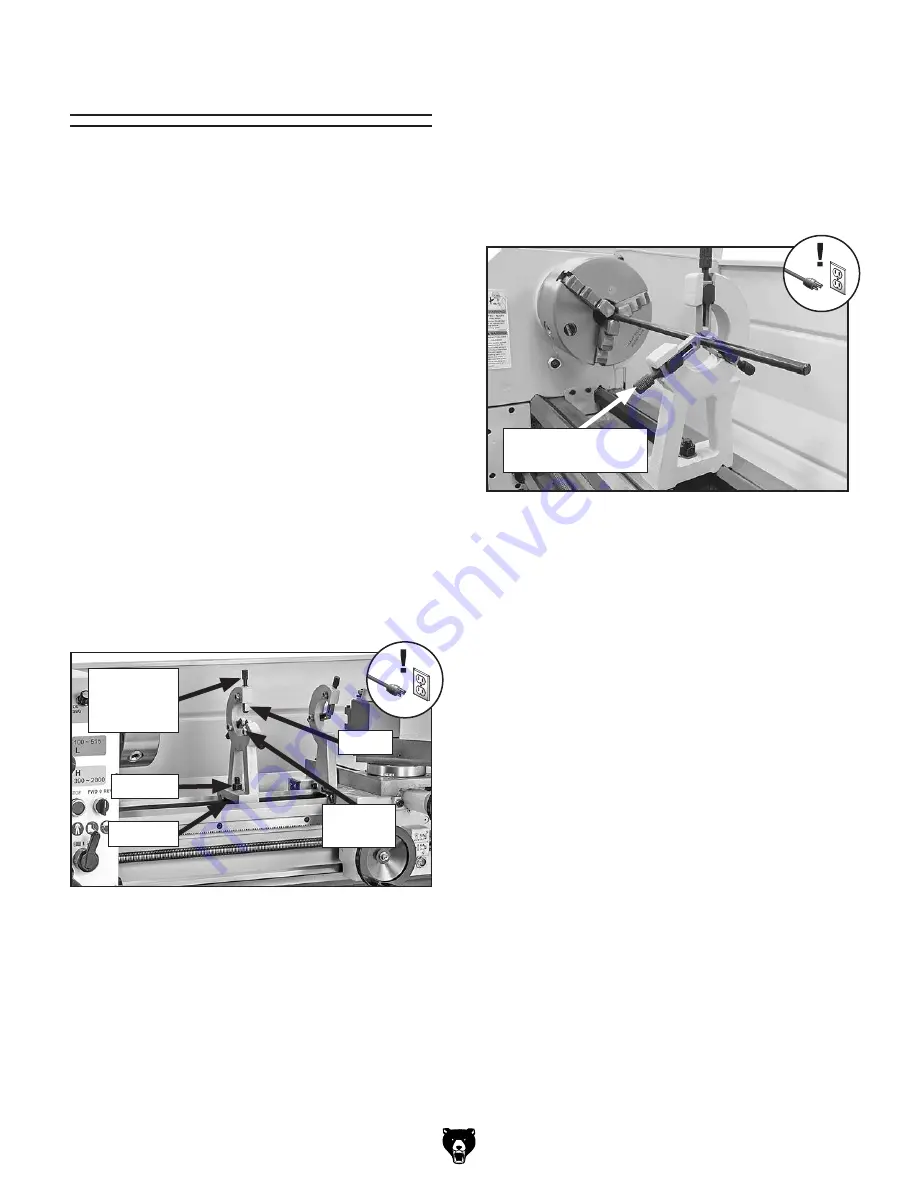

Steady Rest

The steady rest supports long shafts and can

be mounted anywhere along the length of the

bedway. Familiarize yourself with the steady rest

components shown below to better understand

the controls before using it.

Tools Needed

Qty

Open-End Wrenches 14, 19mm ........................ 1

Hex Wrench 5mm .............................................. 1

To install and use steady rest:

1. DISCONNECT MACHINE FROM POWER!

2. Thoroughly clean all mating surfaces, then

place steady rest base on bedways so trian-

gular notch fits over bedway prism.

3. Position steady rest with base clamp where

required to properly support workpiece, then

tighten hex nut shown in

Figure 49 to secure

it in place.

4. Loosen finger lock nuts (see Figure 49) so

position of fingers can be adjusted.

Figure 50. Example of workpiece mounted in

steady rest.

Finger Adjustment

Knob (1 of 3)

6. Tighten finger lock nuts to secure settings.

Note: To reduce the effects of friction, lubri-

cate the fingers with anti-sieze lubricant such

as Grizzly Model T23962 ISO Moly-D Way

Oil (see

Accessories on Page 57) during

operation.

Figure 49. Steady rest components.

Hex Nut

Finger

Adjustment

Knob

Finger

Lock Nut

Finger

Hex Bolt

5. Use finger adjustment knobs (see Figure

50) to position fingers so they just touch

workpiece without causing deflection.

Note:

The maximum quill travel is 3

1

⁄

8

", but

we do not recommend extending the quill

more than 2" or stability and accuracy will be

reduced.

Summary of Contents for G0949G

Page 108: ......