G1022 Series Contractor Saws

-51-

REF

PART #

DESCRIPTION

REF

PART #

DESCRIPTION

97

PRP02M

ROLL PIN 3 x 16

98

PN05M

HEX NUT M16-1.5

99 P1022090

FRONT

TRUNNION

100

PRP06M

ROLL PIN 5 X 24

101

PSS04M

SET SCR M6 - 1.0 x 12

102

P1022102

WAVY WASHER

103

PW03M

FLAT WASHER 6MM

104

PB08M

HEX BOLT M6-1.0 x 20

105

PB10M

HEX BOLT M6-1.0 x 25

106

PN01M

HEX NUT M6-1.0

107

P1022107

SET PLATE

108

P1022108

LINKING BAR

109

P1022109

SPACER

110

P1022110

ECCENTRIC SLEEVE

111

P1022111

WORM SHAFT

112

P1022112

SPACER

113

P1022113

ARBOR BRACKET

114

P1022114

ARBOR BRACKET PIN

115

P1022115

ARBOR NUT

116

P1022116

FLANGE

118

P1022118

BLADE ARBOR

120

P6203

BEARING 6203-2RS

122

PK01M

KEY 5 x 5 x 22MM

123

P1022123

WORM

124

P1022124

HEX NUT M17

125

P1022125

SPINDLE PULLEY

125-1 P1022125-1

MOTOR PULLEY

126

PSS03M

SETSCREW M6-1.0 x 12

127

P1022127

REAR TRUNNION

128

P1022128

REAR BRACKET

129

P1022129

MOTOR BRACKET

130

PSS04M

SETSCREW M6-1.0 x 12

131

P1022131

MOTOR PLATE ROD

132

P1022132

MOTOR PLATE

133

PB07M

HEX BOLT M8-1.25 x 25

134

PW01M

FLAT WASHER 8MM

135

PLW06

LOCK WASHER

5

⁄

8

"

136

PN03M

HEX NUT M8-1.25

137

PN05M

HEX NUT M16-1.5

138

P1022138

SHAFT

139

P1022139

BRACKET

140

PB26M

HEX BOLT M8-1.25 x 30

141

PB03M

HEX BOLT M8-1.25 x 16

142

P1022142

CONNECTING PLATE

143

PN03M

HEX NUT M8-1.25

144

PW01M

FLAT WASHER 8MM

145

P1022145A

SWITCH BRACKET

146

P1022146

SWITCH

147

PWRCRD110S

POWER CORD

147-1 PWRCRD110L

MOTOR CORD

148

P1022148

SPANNER WRENCH

149

P1022149

PULLEY GUARD BRACKET

150

PB10

HEX BOLT

1

⁄

4

"-20 x 2"

152

P1022152

SLEEVE

153

P1022153

PULLEY COVER

154

PWN02

WING NUT

1

⁄

4

"-20

155

P1022Z155

UPPER BRACKET - LONG

155-1 P1022Z155-1

UPPER BRACKET - SHORT

155-2 P1022Z155-2

LOWER BRACKET - SHORT

155-3 P1022Z155-3

LOWER BRACKET - LONG

156

P1022156

WIRE CLAMP

157

PS08M

PHLP HD SCR M5-0.8 x 12

158

PN06M

HEX NUT M5-0.8

159

PVA43

V-BELT A-43

160

G2535

MOTOR 1

1

⁄

2

H.P.

161

P1022161

STRAIN RELIEF

(Not Shown)

162

P1022162

SUPPORTING ARM

163

P1022163

RETAINER

164

P1022164

PAWL

166

P1022Z166

PIN

167

P1022167

SPACER

171

PB47M

HEX BOLT M6-1.0 x 40

173

P1022Z173

PIVOT PIN

174

P1022Z174

GUARD

175

P1022Z175

RETAINER

176

P1022068

SPRING

179

PLN03M

LOCK NUT M6-1.0

180

PN02M

HEX NUT M10-1.5

181

P1022181

SWITCH GUARD

182

PS02M

PHLP HD SCR M4-0.7 X 12

183

PB39M

HEX BOLT M6-1.0 x 50

250

P1022Z250

CLAMP

251

PS05M

PHLIP HD SCR M5-0.8 X 8

252

P1022Z252

SPRING

325

P1022SM325 WARNING LABEL

326

P1022SM326 ELECTRICITY LABEL

327

P1022SM327 SAFETY GLASSES LABEL

328

P1022SM328 MACHINE ID LABEL

329

P1022SM329 BLADE GUARD LABEL

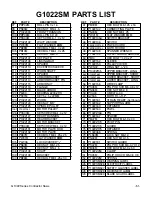

G1022SM PARTS LIST

Summary of Contents for G1022PRO

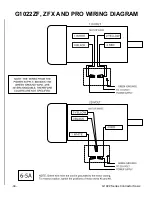

Page 45: ...G1022 Series Contractor Saws 43 G1022SM AND Z WIRING DIAGRAM...

Page 46: ...44 G1022 Series Contractor Saws G1022ZF ZFX AND PRO WIRING DIAGRAM...

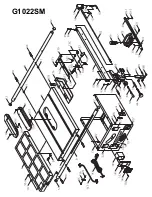

Page 49: ...G1022SM...

Page 50: ...G1022SM...

Page 51: ...G1022SM...

Page 55: ...G1022Z...

Page 56: ...G1022Z...

Page 57: ...G1022Z...

Page 61: ...G1022ZF ZFX PRO...

Page 62: ...G1022ZF ZFX PRO...

Page 63: ...G1022ZF ZFX PRO...

Page 71: ......

Page 72: ......