G1022 Series Contractor Saws

-5-

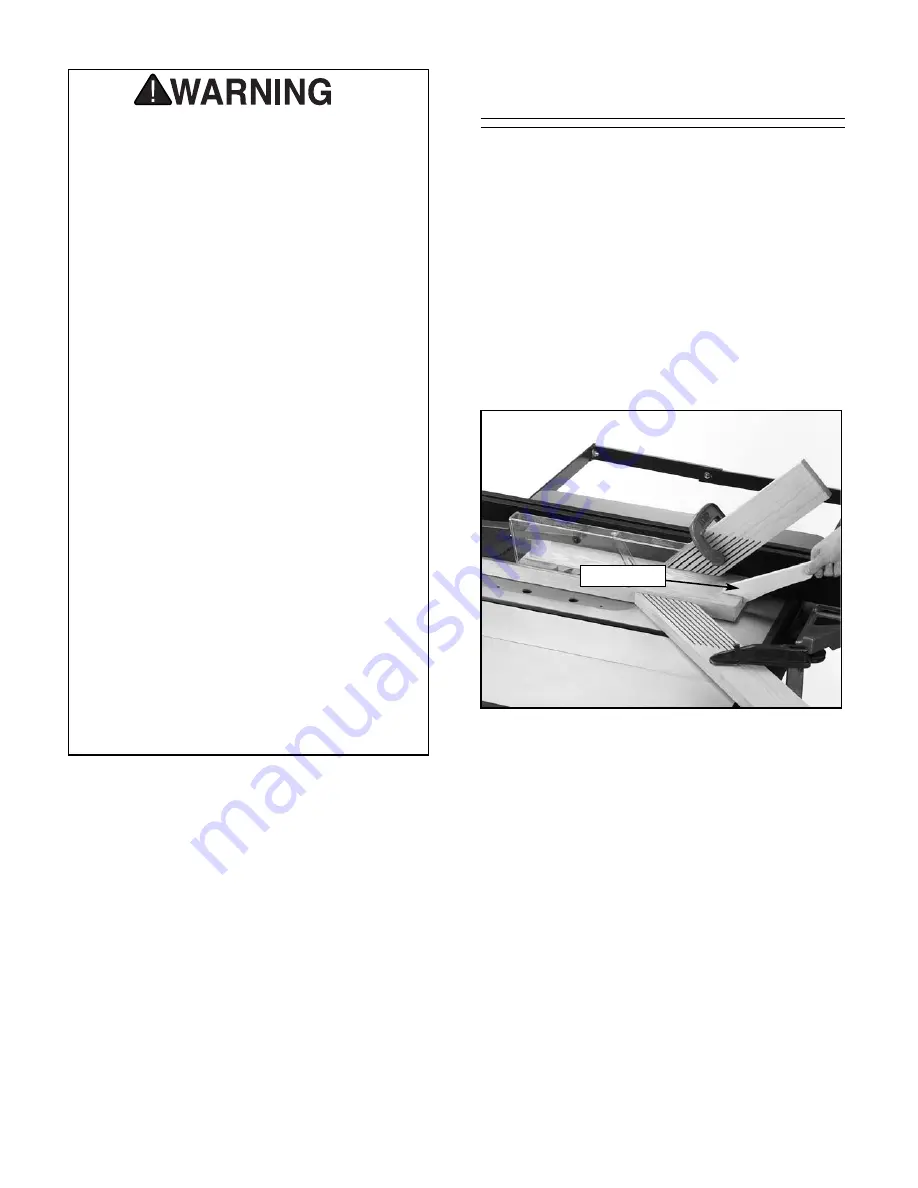

Push Sticks

The use of push sticks, particularly when cutting

small or narrow workpieces, provides a double

benefit for saw operators. The push stick pro-

vides added leverage, enabling the operator to

keep the workpiece firmly supported against the

fence and table. At the same time, the push stick

keeps the operator’s hand safely away from the

rotation of the saw blade as shown in

Figure 1

.

See the template on

Page 62

of the manual for

construction details, or purchase one from the

Grizzly catalog.

Zero Clearance Table Inserts

Ideal for use when ripping thin strips or making

bevel cuts, these prevent tearout and jammed

blades by supporting material close to the blade.

Use the standard table insert as a template when

creating additional inserts from wood or plywood.

Blade slot inserts can be custom cut for specific

blade angles by raising the running blade into an

uncut insert at the angle you desire. Be sure to

make an additional slot for the blade splitter. We

also carry a wide selection of table inserts shown

in

Figure 2

in the Grizzly catalog. Be sure to hold

the insert firmly in place with a piece of wood

when creating slots. Never hold the table insert

with your hand while cutting new slots.

Safety Accessories

Statistics prove that most common acci-

dents among table saw users can be

linked to kickback. Kickback is typically

defined as the high-speed expulsion of

stock from the table saw toward its opera-

tor. In addition to the danger of the opera-

tor or others in the area being struck by

the flying stock, it is often the case that

the operator’s hands are forced into the

blade during the kickback. The following

can help minimize kickbacks.

1. Use your blade guard and splitter.

2. Never for any reason place your hand

behind the blade. Should kickback

occur, your hand will be pulled into the

blade.

3. Inspect splitter for alignment between it

and your blade.

4. Never use the fence as a guide for cross-

cutting.

5. Never attempt freehand cuts.

6. Use a push stick or featherboard to

maintain control of your workpiece.

7. Feed cuts through to completion.

8. Stand to the side when ripping.

9. Ensure your fence and miter slot are par-

allel to the blade.

If you do not have a clear understanding of

kickback and how it occurs, do not operate

this table saw.

Figure 1.

Push Stick.

Push Stick

Summary of Contents for G1022PRO

Page 45: ...G1022 Series Contractor Saws 43 G1022SM AND Z WIRING DIAGRAM...

Page 46: ...44 G1022 Series Contractor Saws G1022ZF ZFX AND PRO WIRING DIAGRAM...

Page 49: ...G1022SM...

Page 50: ...G1022SM...

Page 51: ...G1022SM...

Page 55: ...G1022Z...

Page 56: ...G1022Z...

Page 57: ...G1022Z...

Page 61: ...G1022ZF ZFX PRO...

Page 62: ...G1022ZF ZFX PRO...

Page 63: ...G1022ZF ZFX PRO...

Page 71: ......

Page 72: ......