Model G1163P (Mfd. Since 7/15)

-21-

SECTION 6: MAINTENANCE

For optimum performance from your machine,

follow this maintenance schedule and refer to any

specific instructions given in this section.

Daily Check:

•

Loose mounting bolts.

•

Worn switch.

•

Worn or damaged wires.

•

Full collection bag.

•

Any other unsafe condition.

Schedule

Since all bearings are shielded and permanently

lubricated, simply leave them alone until they

need to be replaced. Do not lubricate them.

Lubrication

Impeller Tightening

DISCONNECT DUST COLLECTOR FROM

POWER

BEFORE

ATTEMPTING

THIS

PROCEDURE!

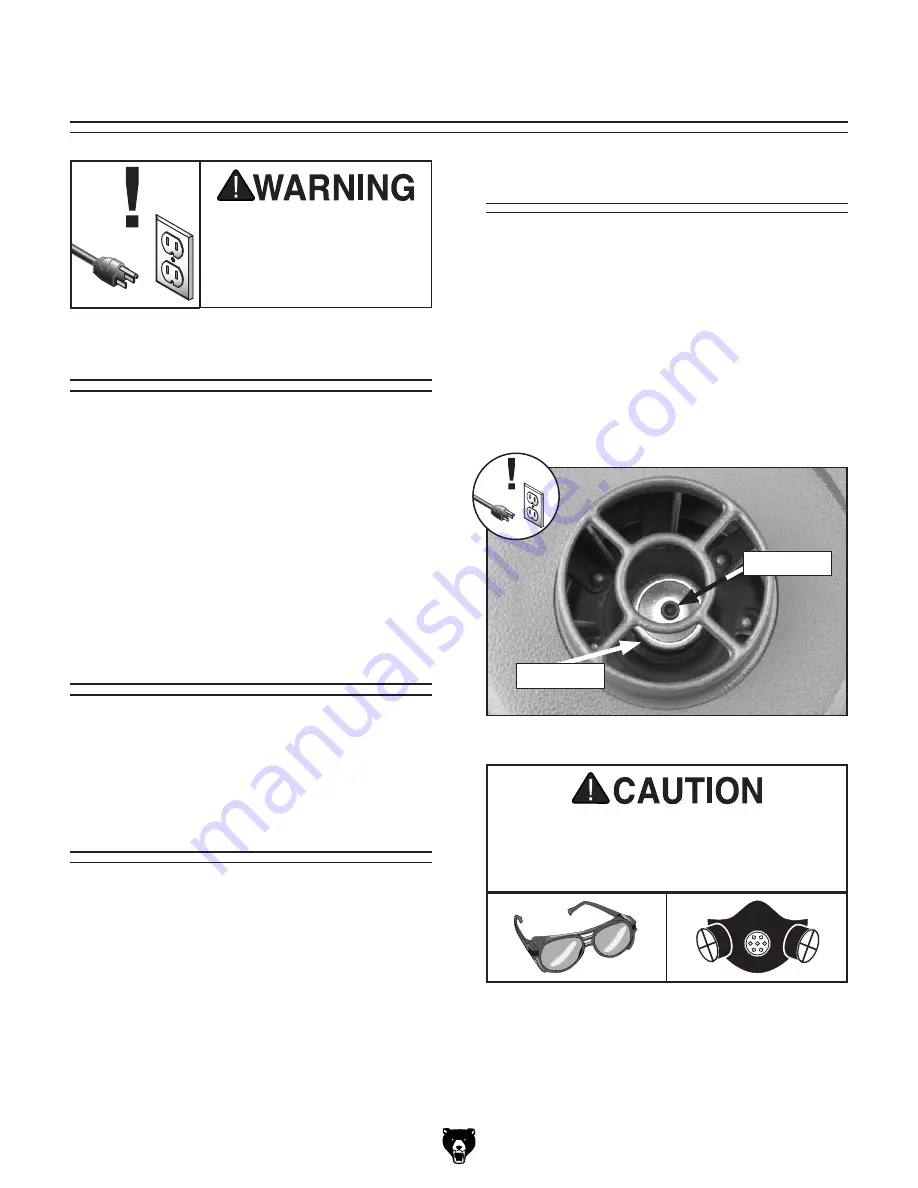

Periodically check the impeller to make sure it is

tight on the motor shaft. Any unusual vibration

or noise may be an indication the impeller has

loosened. A set screw and a left-hand cap screw

secure the impeller to the shaft. These can be

accessed through the inlet cover, as shown in

Figure 23. Tighten the fasteners as needed.

Figure

23

. Impeller screw locations.

Cap Screw

Set Screw

Always empty the collection bag on a regular

basis. Emptying the collection bag allows the

machine to operate at a much higher level of effi-

ciency. Always wear the appropriate respirator or

dust mask and safety glasses when emptying the

collection bag. Small dust particles can escape

the bag during emptying, causing them to become

airborne and easily inhaled. This microscopic air-

borne dust is extremely unhealthy to breathe and

can cause serious health problems.

Bag Cleaning

Always wear a respirator and safety glasses

when emptying the dust collection bag

on the dust collector. Sawdust may cause

allergic reactions or respiratory problems.

To reduce risk of shock or

accidental startup, always

disconnect machine from

power before adjustments,

maintenance, or service.

Summary of Contents for G1163P

Page 32: ......