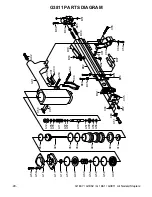

G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers

-9-

SECTION 4: MAINTENANCE

Maintenance requirements are minimal for these

nailers. The two most common problems with any

nailer are jamming and damaged drivers. In both

cases, the nailer will need to be partially disas-

sembled to make the repairs.

The third most common problem is worn out O-

rings. Consult the Grizzly service staff for special

instructions if needed. Grizzly has replacement

parts and special O-ring rebuilding kits available

for these tools.

WARNING: All inspections and/or any mainte-

nance is to be performed with the air supply

disconnected from the tool.

Inspect and maintain the following items

daily:

1.

Check the air nailer for any loose bolts or air

leaks. Loose bolts should be retightened.

Make sure that all lock washers are in place.

Air leaks are an indication that internal seals

are worn or nicked and should be replaced.

2.

Make sure the safety nose and trigger are

functioning properly. Repair as necessary.

Do not use the nailer with a broken or modi-

fied safety nose.

3.

Inspect the automatic lubricating system if

applicable and fill as required. Inspect the in-

line air and water filters if applicable and

change or clean as necessary.

4.

Inspect the compressor regulator and/or in-

line regulator to ensure that they are set cor-

rectly. Adjust accordingly.

General

CLEANING:

Keep the nailer nose as clean as

possible. Dirt and debris have a tendency to work

their way into the nailer from the nose. Wipe off

any dirt that collects on the outside of the nailer

before connecting it to the air supply.

OILING:

Keep the nailer oiled. Use special pneu-

matic tool oil to keep internal parts well lubricat-

ed. This tool oil is available through the Grizzly

Catalog (G2820).

If your air supply is not pre-lubricated, you must

add 2 drops of oil directly into the air nozzle at the

rear of the nailer each time the magazine is

loaded.

NEVER USE

any oil that will corrode the

rubber O-ring seals such as motor oil, detergent

oils, or oils that are used as solvents. Avoid over-

oiling.

IMPORTANT:

When you first pick up an air acti-

vated nailer,

ALWAYS ASSUME THAT IT IS

LOADED.

Open the magazine and inspect for

any nails or staples before connecting it to the air

hose.

Do not

connect the air supply until you are

in position and ready to operate the nailer.

Cleaning & Oiling

DO NOT load or service any pneumatic nail-

er or stapler without first disconnecting it

from its air source. Failure to do so could

result in a misfire and possible injury.

Ensure that the safety mechanism is work-

ing properly each time you use this tool.

Under no circumstances should the safety

be modified or disabled. Serious injury

could occur.