-10-

G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers

Aligning Nosepiece

The nosepiece may become misaligned if the

nailer has been dropped or otherwise mishan-

dled. Misfiring and/or jamming will result if the

nosepiece is misaligned – but correcting the

problem is simple.

To align the nosepiece:

1.

Remove the nosepiece cover.

2.

Remove fasteners and visually inspect to

see if the nail slot in the nosepiece is aligned

with the nail slot in the magazine. If it is hard

to tell, put a nail in and see if it slides through

both slots easily.

3.

If the nosepiece is misaligned, loosen the

cap screws that secure it to the magazine

and shift it until it lines up.

4.

Re-assemble.

5.

Do not

put any fasteners into the magazine.

Connect the air hose.Check for any leaking

air. You will hear it hissing or feel it rushing

through the spaces.

6.

If everything sounds normal, press the safe-

ty nose down on a piece of wood and pull the

trigger a couple of times. Air should be

exhausted normally each time.

Jamming

To repair a jam:

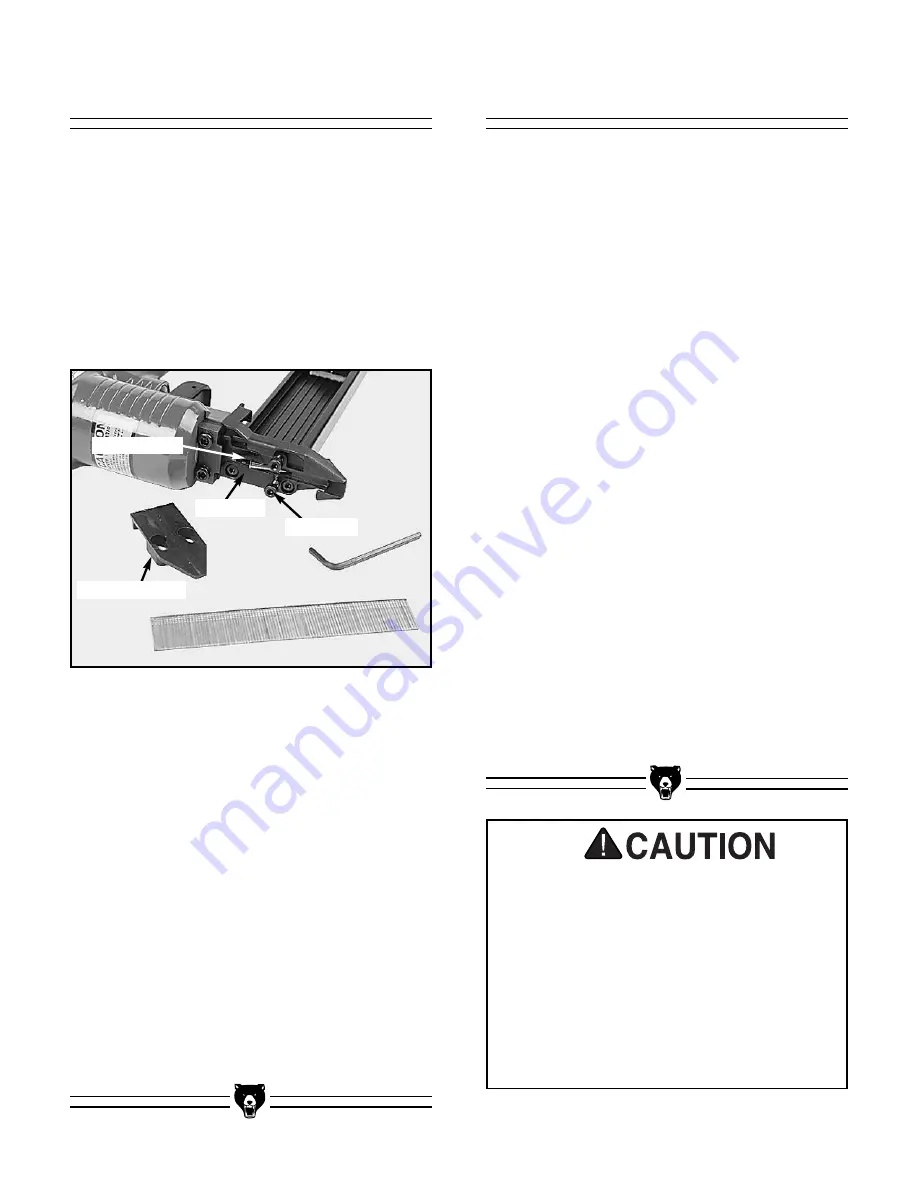

1.

Remove any fasteners remaining in the gun.

2.

Partially unscrew the cap screws that hold

the nosepiece cover in place. Slide the nose-

piece cover down and pull it off.

Figure 5.

(

G1861:

Remove the safety tip before

removing the nosepiece cover.)

4.

Remove any fasteners lodged in the nailer

nose.

5.

Re-attach the nosepiece cover. Make sure it

lines up properly.

G1861:

Attach the safety

tip.

6.

Load fasteners and connect the nailer to the

air supply.

7.

Make sure the safety tip is functioning cor-

rectly and that it slides freely. Test fire into a

sample piece.

If jamming persists, make sure you are using fas-

teners within the size range of this nailer. If jam-

ming is due to worn or broken parts, repair or

replace them before placing the nailer back into

service.

Jammed Brad

Nosepiece Cover

Cap Screw

Nosepiece

DO NOT attempt to repair or service this

gun without ensuring that all nails or sta-

ples have been removed and that the gun is

disconnected from its air source. Use

extreme care when testing after freeing

jams or after re-loading. Always wear

approved safety glasses or goggles and

quality hearing protection when operating

pneumatic guns or other woodworking

tools and machinery. Failure to do so could

result in serious personal injury.